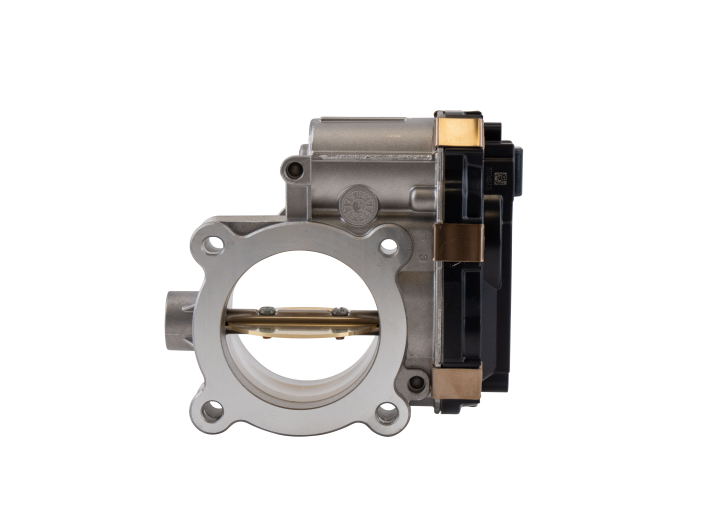

Throttle Body

Throttle Body

Description

The electronic throttle valve is installed between the mass air flow sensor and the intake manifold. It regulates the air that is drawn in by the engine. The ratio of air to fuel changes depending on the opening angle of the throttle valve.

The position of the accelerator pedal and any other information from the engine control unit (ECU) are permanently synchronised. Based on all the measured data, the ECU determines the best possible position for the throttle valve. The throttle valve is actuated by a signal from the engine control unit. This electronic control is helpful for very efficient engine control.

Possible sources of faults are contamination due to deposits of dirt or soot or foreign bodies. In addition, the gears in the throttle valve are subject to signs of wear and can therefore become damaged over time. Other faults can be defects in the motor or potentiometer.

Hitachi Astemo has extensive and profound experience with electronic throttle bodies, as we have been supplying all established vehicle manufacturers for decades.

The Hitachi Astemo Aftermarket product programme currently consists of around 100 products.

With our current programme, we cover more than 50 million vehicles on the road in the EMEA region*. As part of the general expansion of our product coverage, we plan to continue to expand our programme significantly in the near future.