High Pressure Pump

High Pressure Pump

Description

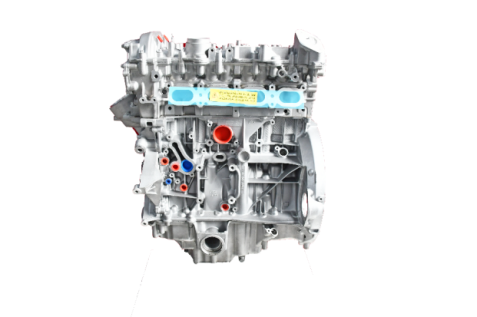

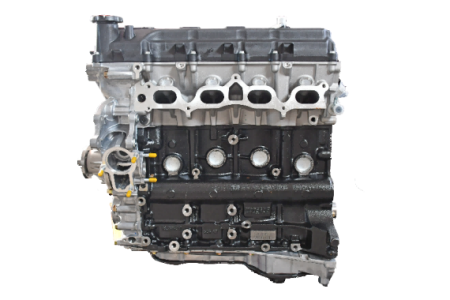

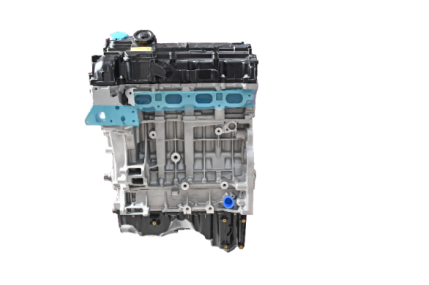

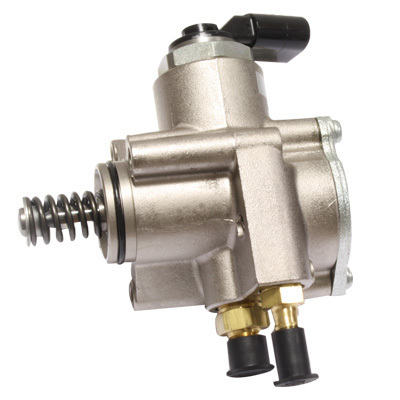

High Pressure Pumps (HPP) are used in modern gasoline engines with direct injection. The HPP is an engine driven demand control supply pump designed to multiply the standard inlet fuel pressure from the fuel pump to the extremely high pressures required on modern direct injection engines. Through gasoline direct injection higher torque can be achieved with the same cubic capacity which increases performance. The extremely fast control valve response time allows the high pressure pump to react better to changes of the gas-pedal position. In partial-load operation there is a measurable amount of fuel savings.

The HPP is supplied with fuel by the fuel pumps at a pressure of approx. 6 bar (87 psi) and boosts the fuel to a pressure up to 110bar (1595 psi) into the common rail. The pump is positioned directly within the engine, because the drive mechanism is mechanical and not electrical.

The pump is operated via an extra cam on the intake camshaft. The output of the HPP is limited by a solenoid valve. Due to safety reasons the solenoid valve is a so-called power-off opened electromagnetic valve. In case the power supply is interrupted, the entire output of the HPP is pumped back via the open valve. The valve is opened once the required minimum pumping pressure has been reached.

The following problems can occur when a high pressure pump is damaged:

- General stuttering of the engine

- Decreased power

- Total breakdown of the engine

Today our product portfolio consists of 60 high pressure pumps which cover a total of 1.390 vehicle types.