Air heater

Description

Advantages

Painting:

- Elimination of orange peel effect

- 50% reduction in drying time

- Easy and quick application

- Exceptional aesthetic result with water-based paints and optimization of their consumption

Industry:

- Heating of compressed air for tools/special applications

- Protection of compressed air powered equipment

- Heating of compressed air for tool defrosting

- Prevention of contaminants and condensation in pressure gauges and instrumentation

- Hot air jet drying in industrial washers for washing metals and mechanical parts

General:

- PID (Proportional, Integral, Derivative) system. The system avoids unnecessary energy consumption and guarantees the maintenance of the set temperature, with a delta of ± 1 °C.

- Flexymaster tube of our own production. Lightweight, easy to handle and extremely flexible, the Flexymaster tube is insulated to maintain the inlet temperature with a maximum loss of 5 °C and is covered with a special protective sheath.

- Flexyhot tube of our own production. Lightweight, easy to handle and extremely flexible. The Flexyhot tube can be supplied either insulated or non-insulated. It allows to have the fluid available immediately at the desired temperature and to keep it constant up to the work point.

- Modular system. Depending on the needs of the end user, the following are supplied on request:

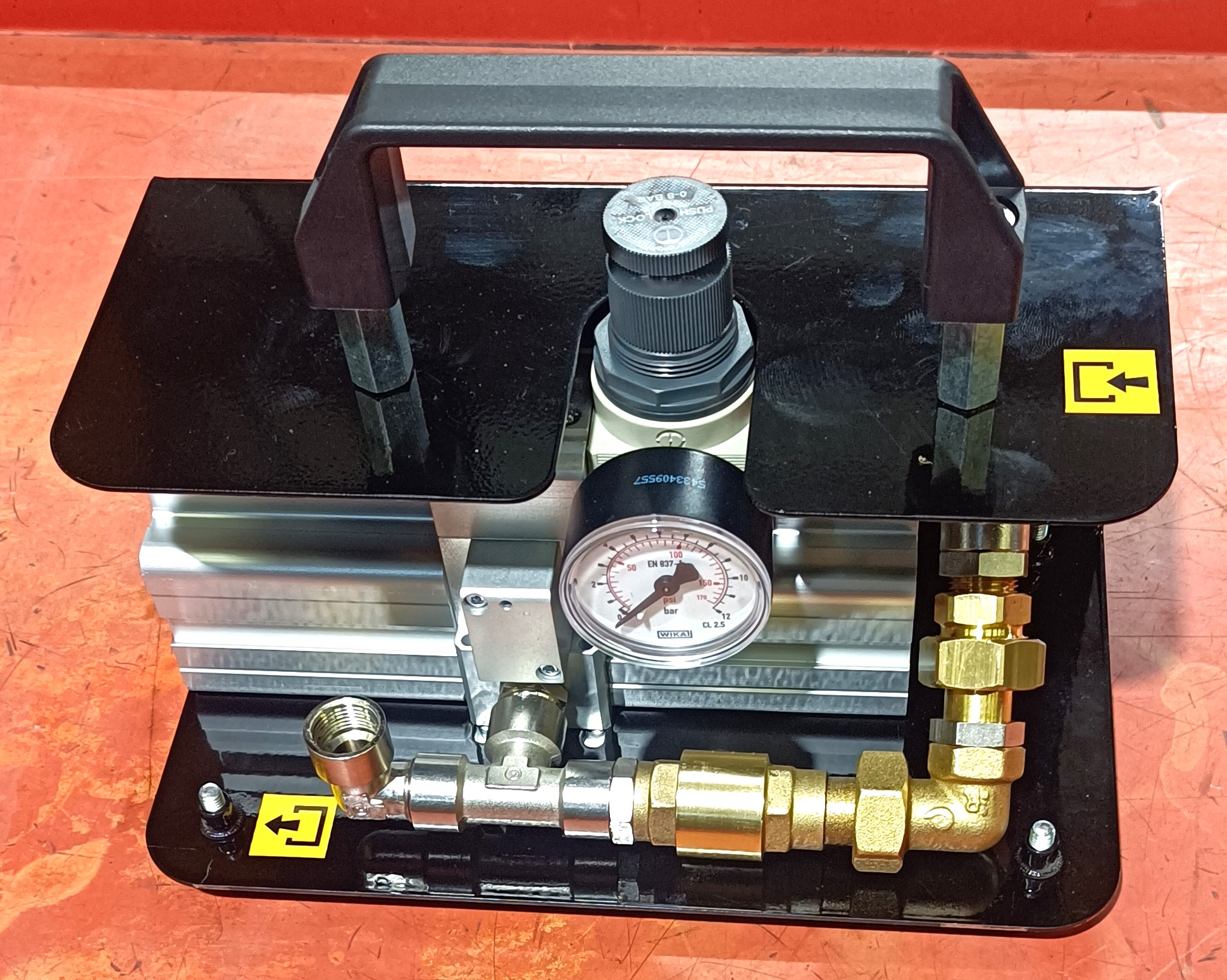

- Pressure reducer that guarantees an inlet air flow at constant pressure

- Solenoid valve that allows the air inlet to be interrupted by simply turning off the heater

- Filter system (active carbon filter and coalescing filter)

- Flexymaster tube

- Self-supporting frame for mobile applications

Application sectors and description

The RACPID 206 heater can be used in the following sectors:

- Bodywork

- Industrial painting

- Wood and furniture industry

- Industry

- Aeronautics

- Naval

- Carpentry

- Medical/dental

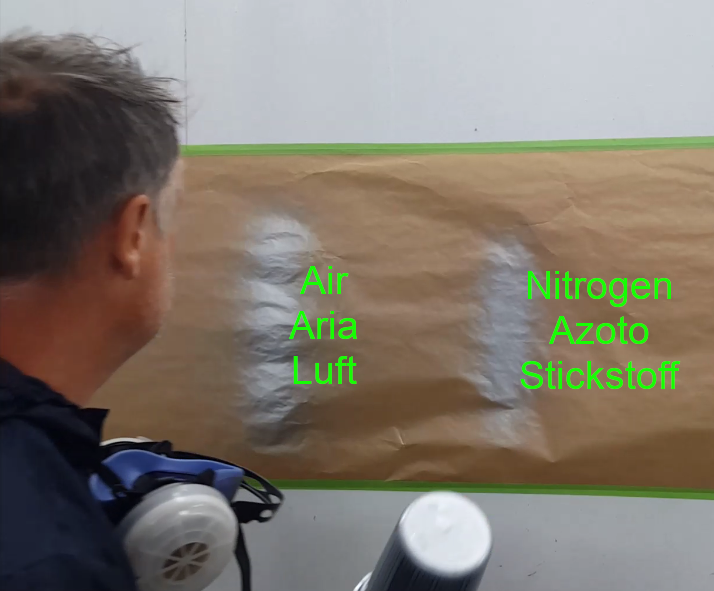

By setting and maintaining a constant outlet temperature, the advantages for painting are evident both during application and drying. Thanks to the RACPID 206, in fact, the problems caused by low temperatures in winter that do not allow the paints to be nebulized at the correct temperatures, and by the relative humidity in summer which, if lower than the dew point of the ambient temperature, can cause condensation that contaminates the paint, are eliminated. Once the paint has been applied, the RACPID 206 can also be used simply to blow hot air onto the surface.

RACPID 206 is not just a thermoregulator, it also offers an optional dual filter system consisting of: a coalescing filter with automatic condensate drain for the removal of oil mists, lubricating oil vapors, cooling oil, etc. which reduces the oil residue in the air to only 0.003 mg/m3 (class 1 - ISO 8573-1:2010) and an active carbon filter that purifies the air to obtain a particulate residue of less than 0.003 µm. After 1,500 hours of operation of the heater, a message appears inviting the replacement of the filters, this message appears both in the version with and without filters.

The RACPID 206 boasts a customized control panel and software based on the PID (proportional, integral, derivative) control algorithm, guarantees the constant maintenance of the set temperature and is able to heat the air up to a maximum of 100 °C. The PID system also reduces unnecessary energy waste.

The electronic controller stores energy consumption data and by entering the kwh cost in the dedicated parameter, it is possible to extract the exact data of the energy cost.

Accessories

To increase the performance of the RACPID 206 heater, we have created the following accessories:

- Flexymaster insulated hose

- Flexyhot heated hose

- Solenoid valve

- Pressure reducer

- Self-supporting frame for mobile applications

Insulated hose Lengths 5 - 10 - 12 m.

Heated hose Lengths 5 - 10 - 12 - 15 m.

Solenoid valve Allows the air inlet to be interrupted by simply turning off the heater

Pressure reducer: Guarantees an inlet air flow at constant pressure

Self-supporting frame for mobile applications Structure specially designed to easily transport the heater

Address

Nitrolaq di Paolo Borsalino

Via Capaccola 58

54100 Massa Massa Carrara

Italien

Telephone+39 348 650 7490

Discover more from us