Oxygen Sensors

Oxygen Sensors

Description

An oxygen sensor is an electronic device that measures the proportion of oxygen in the gas being analysed. It sends a digital signal to the ECU that indicates if the mixture of air/fuel is poor or rich, according to the stoichiometric concentration of fuel engines.

FAE’s oxygen sensors are manufactured in a cleanroom type ISO-7, 700 m².

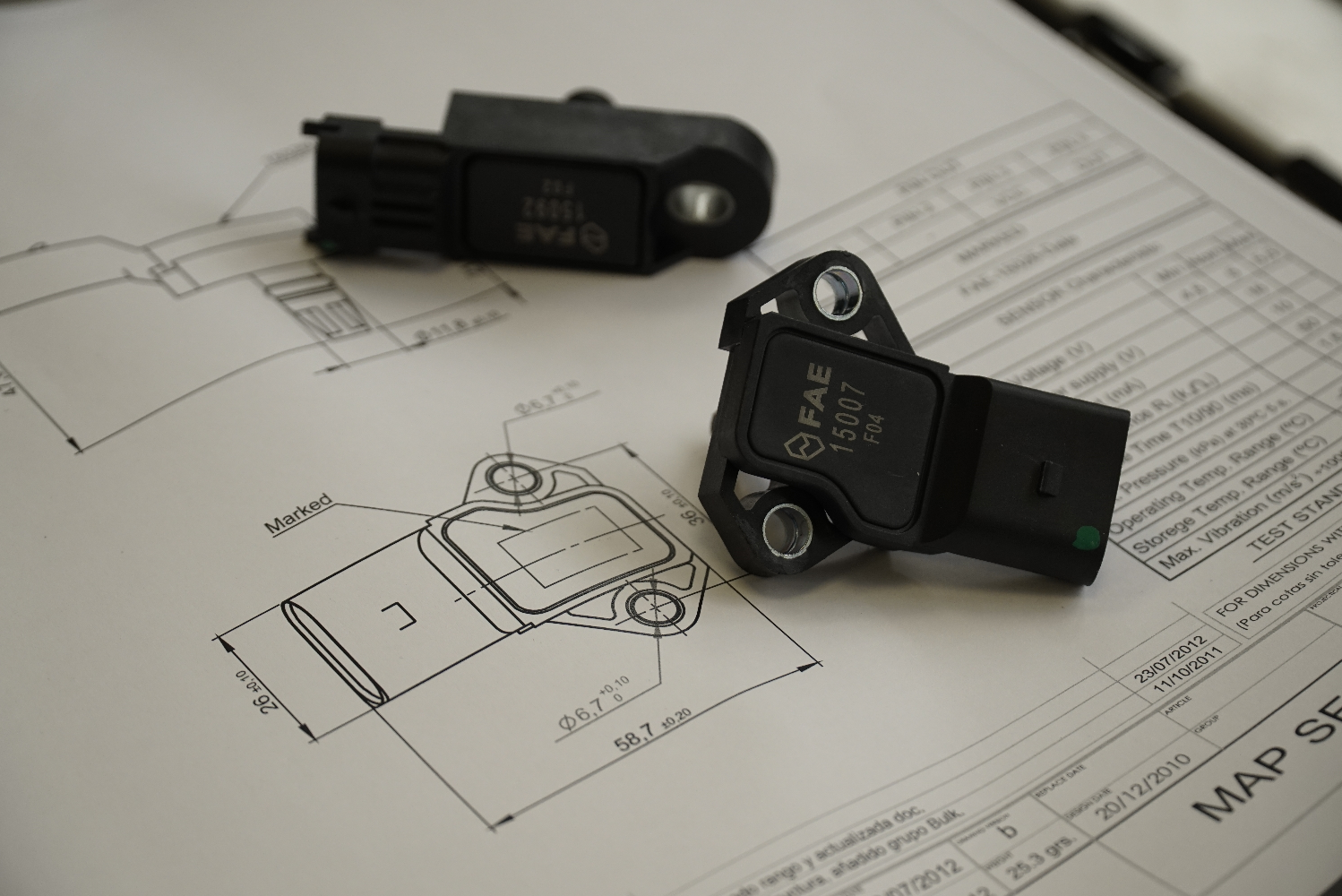

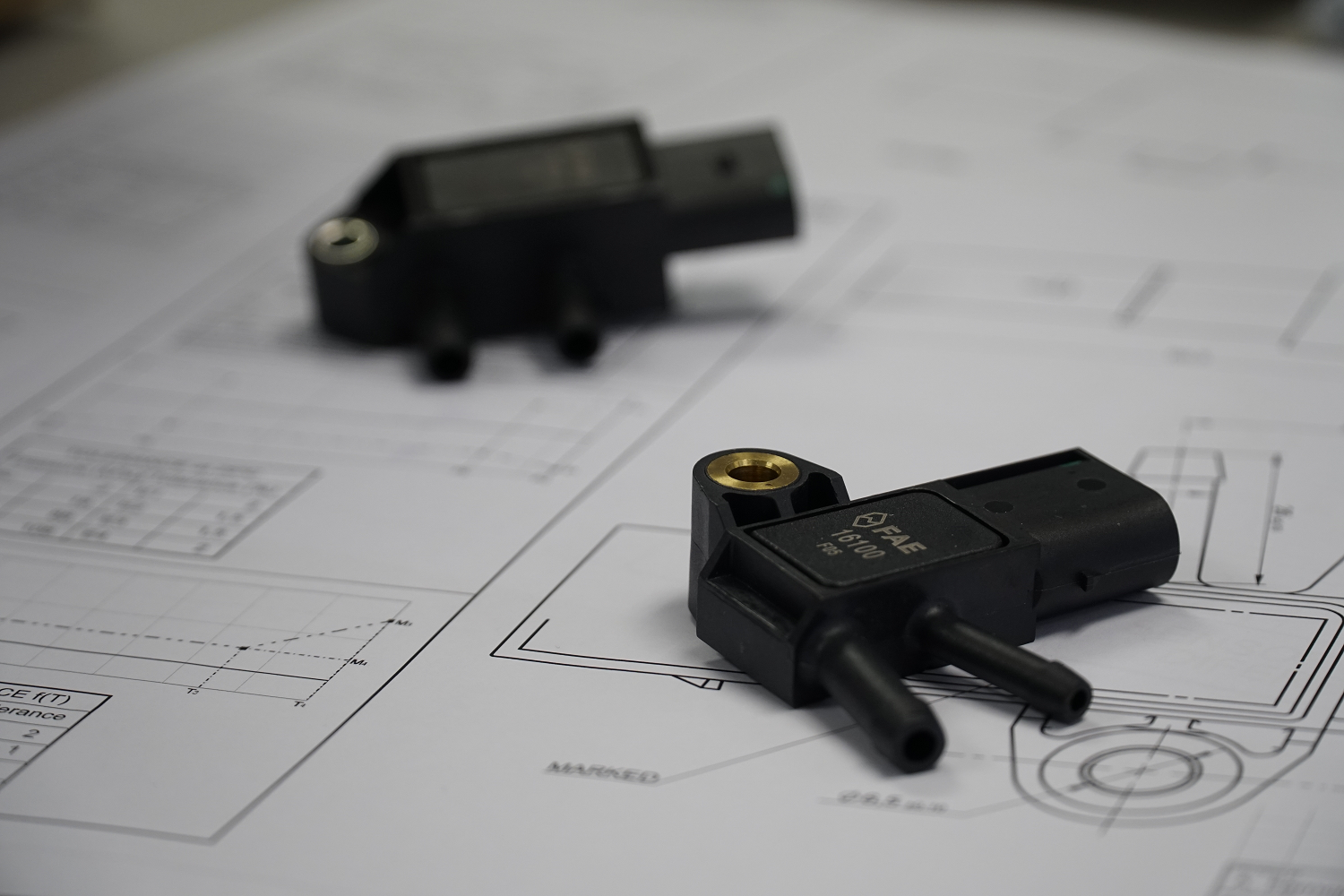

A high skilled team of passionate engineer’s design and develop our oxygen sensors to ensure the best response and quality of the product.

To keep up with the market tendencies FAE is continuously researching the latest technologies and developments.

Besides manufacturing Planar Oxygen Sensors, FAE focused last year’s particularly developing and manufacturing on Wide Band Sensors (WB) and Air Fuel Ratio Sensors (AFR).

WB are equipped with 6 or 7 pin connectors and their response is proportional to the fuel-air ratio, in contrast to previous models that distinguish only between poor or rich mixture. The architecture of this sensor consists of two measuring cells, a heating element, and a calibration resistance placed in the connector housing.

AFR, 4 wires, this sensor is equivalent in terms of response to a 5-wire WB because its signal is proportional to the lambda, which leads to a more efficient control of emissions, but unlike the 5-wire, this sensor requires single cell electrode.

Without a doubt, WB and AFR are technologies that more and more vehicles will use, thanks to its precision in measuring the level of oxygen in exhaust gases, to regulate combustion and achieve the maximum reduction in emissions from our vehicles.

Finally, FAE’s motorbike oxygen sensors are top of the notch and are highly demanded by motorbike manufacturers worldwide.

To meet customer and market needs FAE’s OEM business unit works closely together with our R+D+i department.