Line for torque converters repairing and restoration

Line for torque converters repairing and restoration

Description

Line for torque converters repairing and restoration

High-quality repair of automatic transmission is impossible without repair of the torque converter (TC). A welded and, at first glance, simple design can hide many problems that cannot be solved without specialized equipment.

Kinergo has developed a line of equipment that can be used to repair TC of any automatic transmission model existing on the market.

TC repair line — is a set of equipment that includes welding machines, test benches, special devices and tooling.

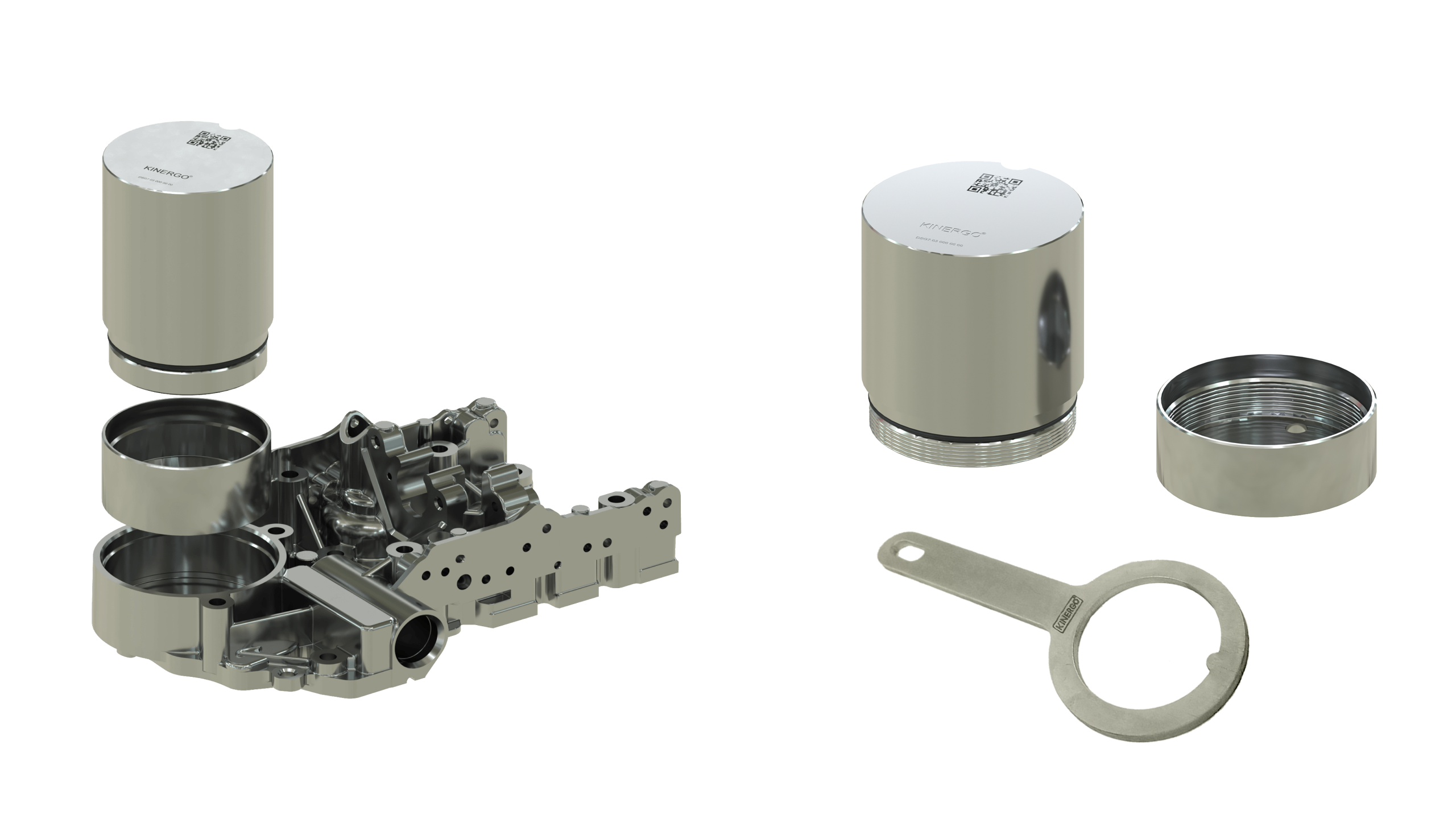

1.Cutting, disassembling:

- PS 07.330 (not in picture) – – a tooling package for a lathe for fixing

the torque converter during its cutting and for processing

its surfaces and diameters.

Includes the faceplate with a diameter of 330 mm

Top row, from left to right in the picture

2.Flaw detection, nodes replacement:

- NF 02.400 – infrared piston bonder

- IN 06.001 – lockup preload tester for ZF6HP-type Torque Converters

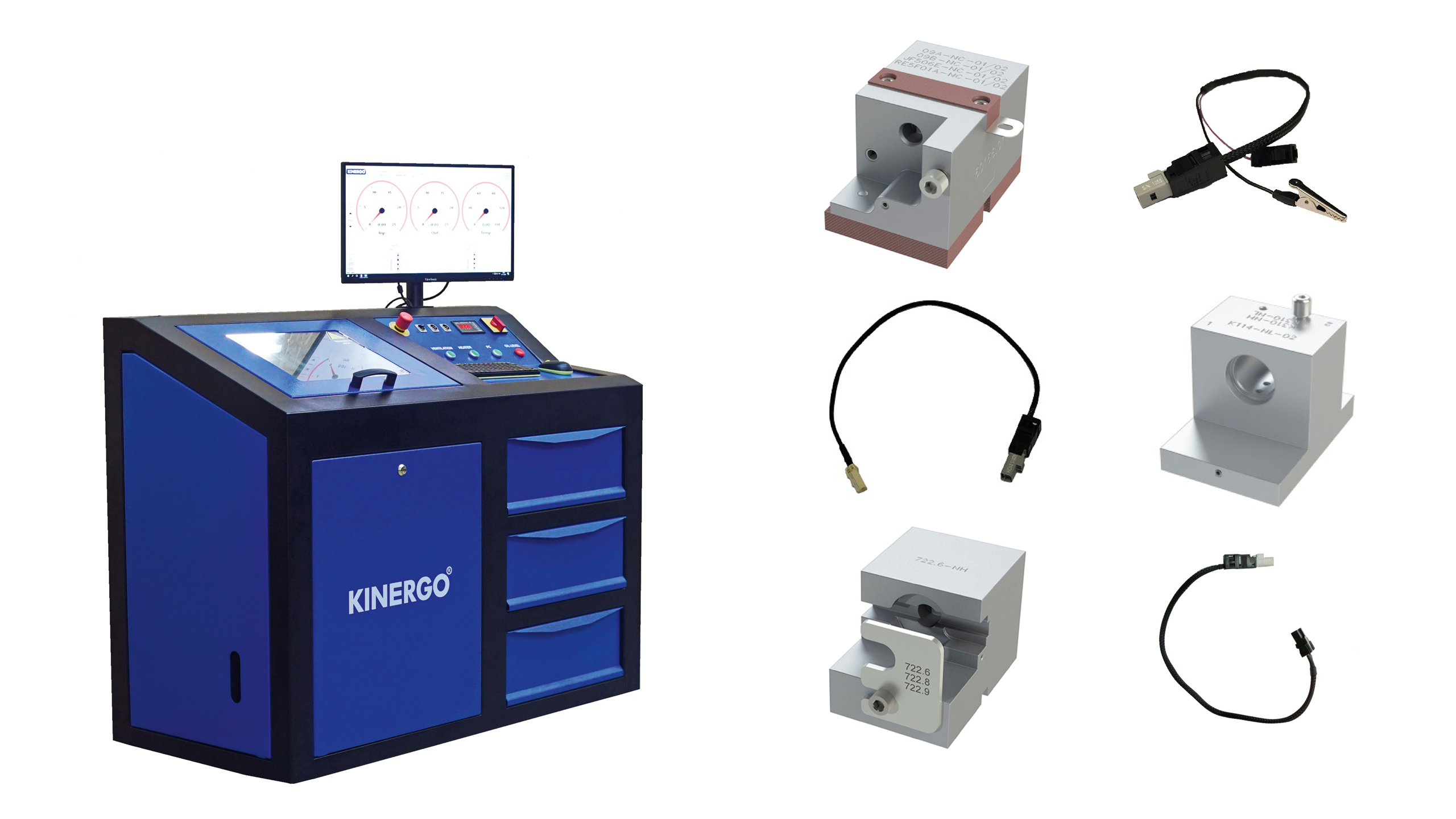

3. Welding:

- SV 10.004 – torque converter welding machine

- OS 10.001 (not in picture) – tooling package for centering and fixing

of the torque converter elements and hubs replacing on the turntable faceplate.

4. Control and parameters verification:

- SG 50.500 – air test stand

- TZ 03.800 – end play gauge stand

- SB 02.350 – The stand is designed to measure the imbalance of torque converters of automatic transmissions in dynamic mode and calculate the masses of corrective loads and their positions.

In 20 years, the company has come a long way from basic understanding the principles of repair to its own technologies for the restoration of automatic transmission torque converters.

The accumulated practical knowledge and experience made it possible to develop a line for the repair of torque converters, which is being modernized and improved to this day.

And for the customers who have bought equipment, a free training program is organized on the basis of the Kinergo technical center.