Description

GRAH Automotive has huge knowledge and know-how to produce wire harnesses for many automotive and non-automotive applications. Our current focus is on low voltage products but the company plan is to expand production portfolio to high-voltage applications.

Our high-runners are for the:

- Outside mirrors

- Sound systems

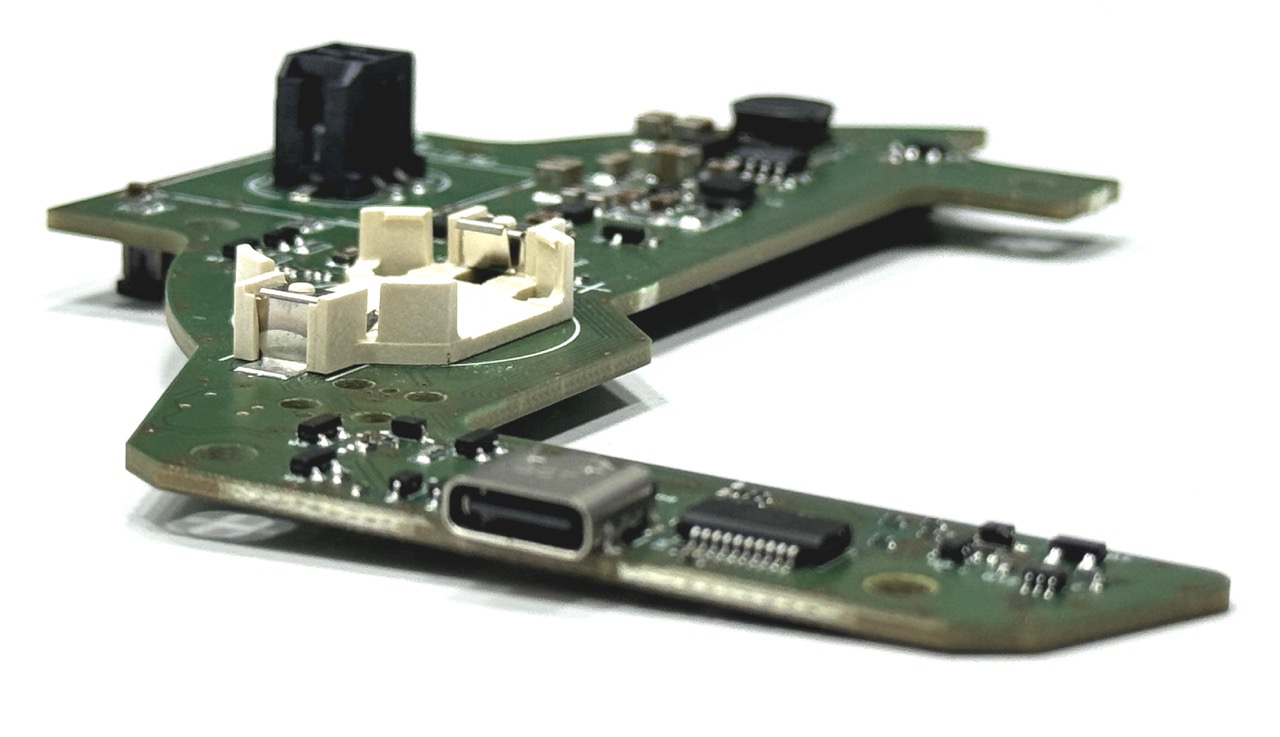

- Mechatronic parts

- Convertible roof systems

- E-charger door flaps

- etc.

Our production is equipped for:

- Automatic wire processing

- Semi-automatic wire processing

- Automatic and semi-automatic multicore cable processing

- Machine and hand taping

- Machine and hand seal application

- Ultrasonic splicing and welding

- Special component (THT) crimping

- Wire tinning

- Wire twisting

- IDC termination

- Macromelt overmoulding.

Our workers are highly specialised for the hand-assembly operations and our Samples Department can help you with any prototype sample that you need.

We have dedicated Samples Shop and Tooling Shop that is helping us to produce the prototypes very fast and to develop and implement product into production.

We also have internal development of testing devices and software and the assembly lines are developed and manufactured by our Technologists.

Every wire harness is tested for conductivity and presence of the components (ie. clips, grommets, special parts, etc) but we can also check special components like hall sensors, reed sensors, pinchstrip activatiors, etc.