ENGINE GASKETS

ENGINE GASKETS

Description

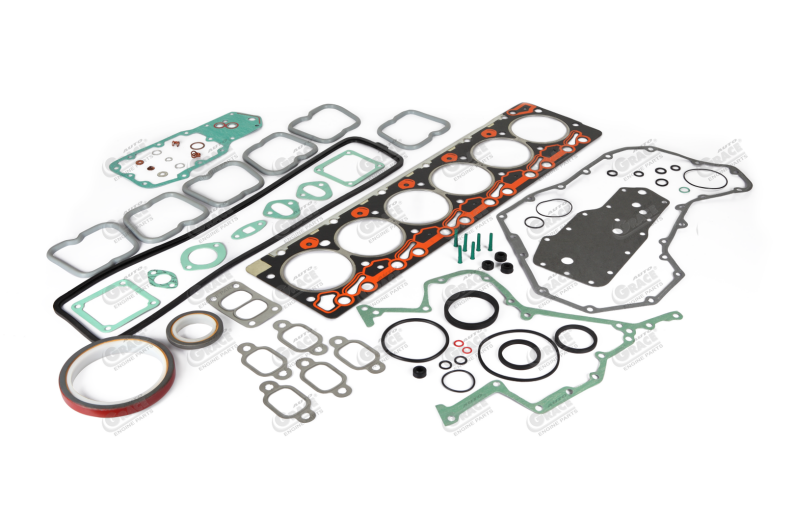

Garima Global makes substantial investment in the development of sealing systems such as overhaul gaskets sets, head sets and lower sets to ensure they offer long and reliable service life even under adverse operating conditions typical to aftermarket including aggressive media, extreme thermal and pressure loads, suboptimal fuel quality etc.

We also supply individual gaskets in a wide variety of materials like multilayer steel, metal-elastomer, asbestos free ferroelastic elastomer, graphite composites, copper composites, cork, rubbers of various grades like Viton®, nitrile etc. These include head gaskets, exhaust and intake manifold gaskets, valve cover gaskets, oil pan gaskets, oil seals and valve stem seals.

These components are sourced from the leading manufacturers of engine gaskets and seals in India and put through intensive quality control before being exporter to our customers. Garima Global supplies the below engine sealing components in its well-known AutoGRACE® brand worldwide in asbestos-free materials to comply with modern environmental norms.