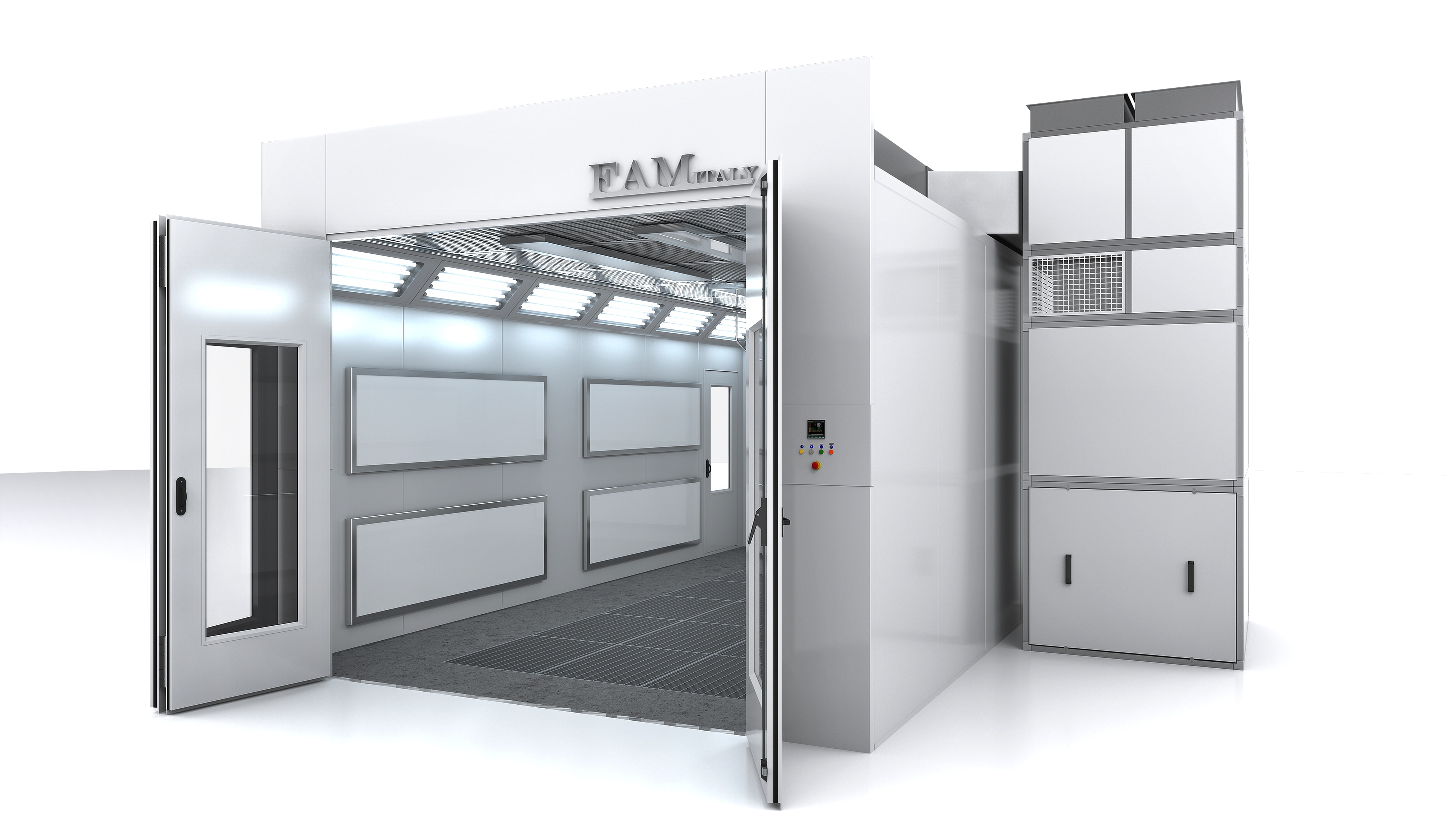

GOLD

The eco-sustainable alternative

The endothermic booth works without burner; during the various phases of manufacturing, heat is generated and diffused inside the booth through radiant panels placed on the walls and on the roof (plenum), heating up the product to be worked through radiation. The panels are easy to install and use even in existing booths.

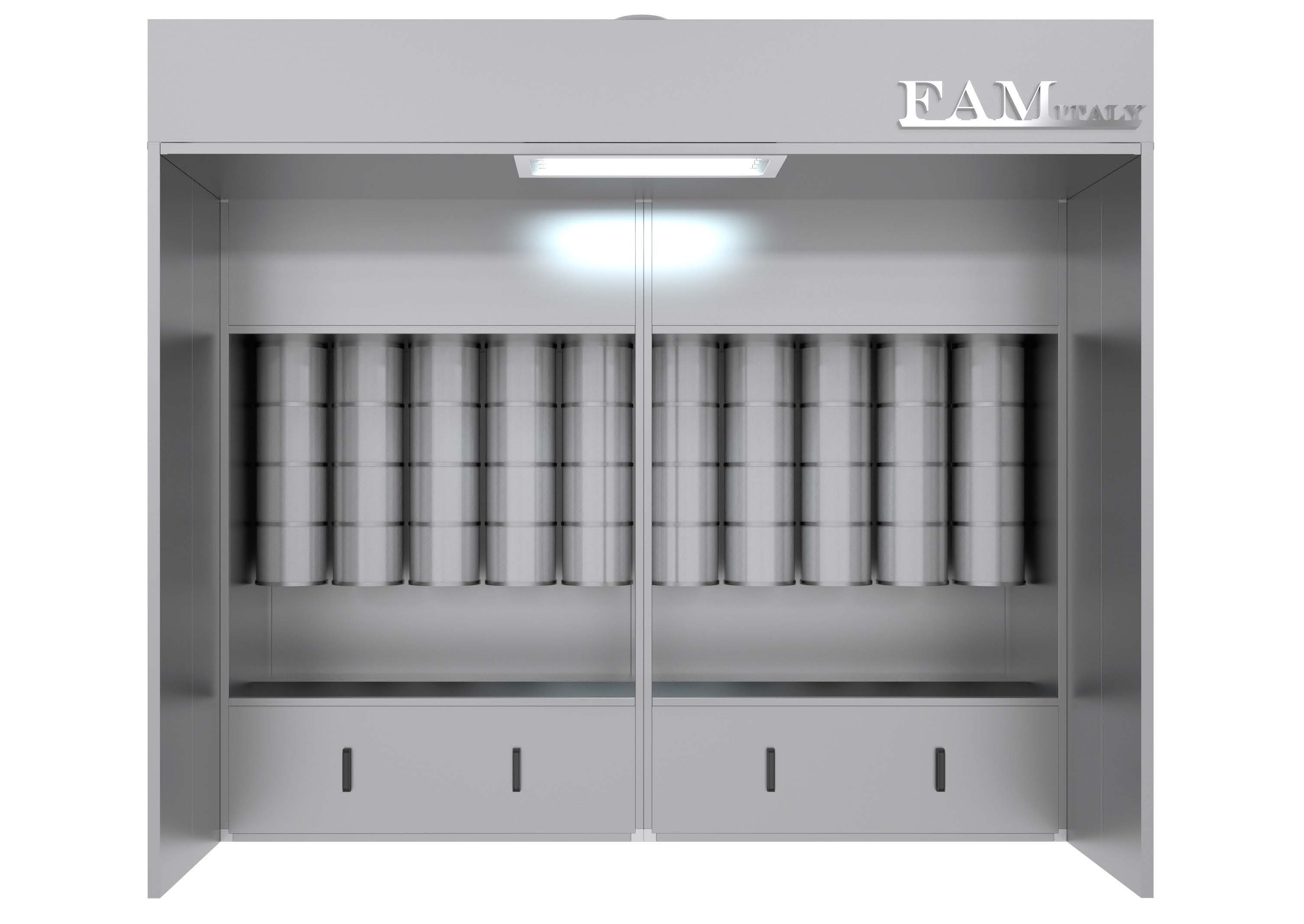

Thanks to the flexibility of our control panel, we can reduce the operating costs, through the cyclical and programmed switch-on of radiant panels, to maintain the temperature of the surface to dry unchanged, with the minimum power consumption. The same control panel allows the partial switch-on of the right and left radiant panels to be able to work only on the surface interested by the painting and drying cycle. Preparation phase: the ignition of panels increases the temperature of the plate exposed to radiation to approx. 25/30°C; preheating time goes from 3 to 5 minutes, according to the room temperature. Painting phase: thanks to radiation, of the heat on the plate, the paint disperses water and solvents faster; in this way the flash-off times between the layers considerably decrease. Drying phase (with programmed ventilation inside the booth of 2 minutes each 10 minutes of work to remove gases originated from the flash-off of the paints. Drying phase: the panels reach their max. temperature in a short time, increasing the plate temperature till 70°C, helping the paint drying process. The reduction of working times involves the reduction of labor costs and the increase of daily production, but the real revelation concerns the cutting of the costs related to the system management. Furthermore, compared with the traditional booth, there is no expulsion of combustion gases into the atmosphere.