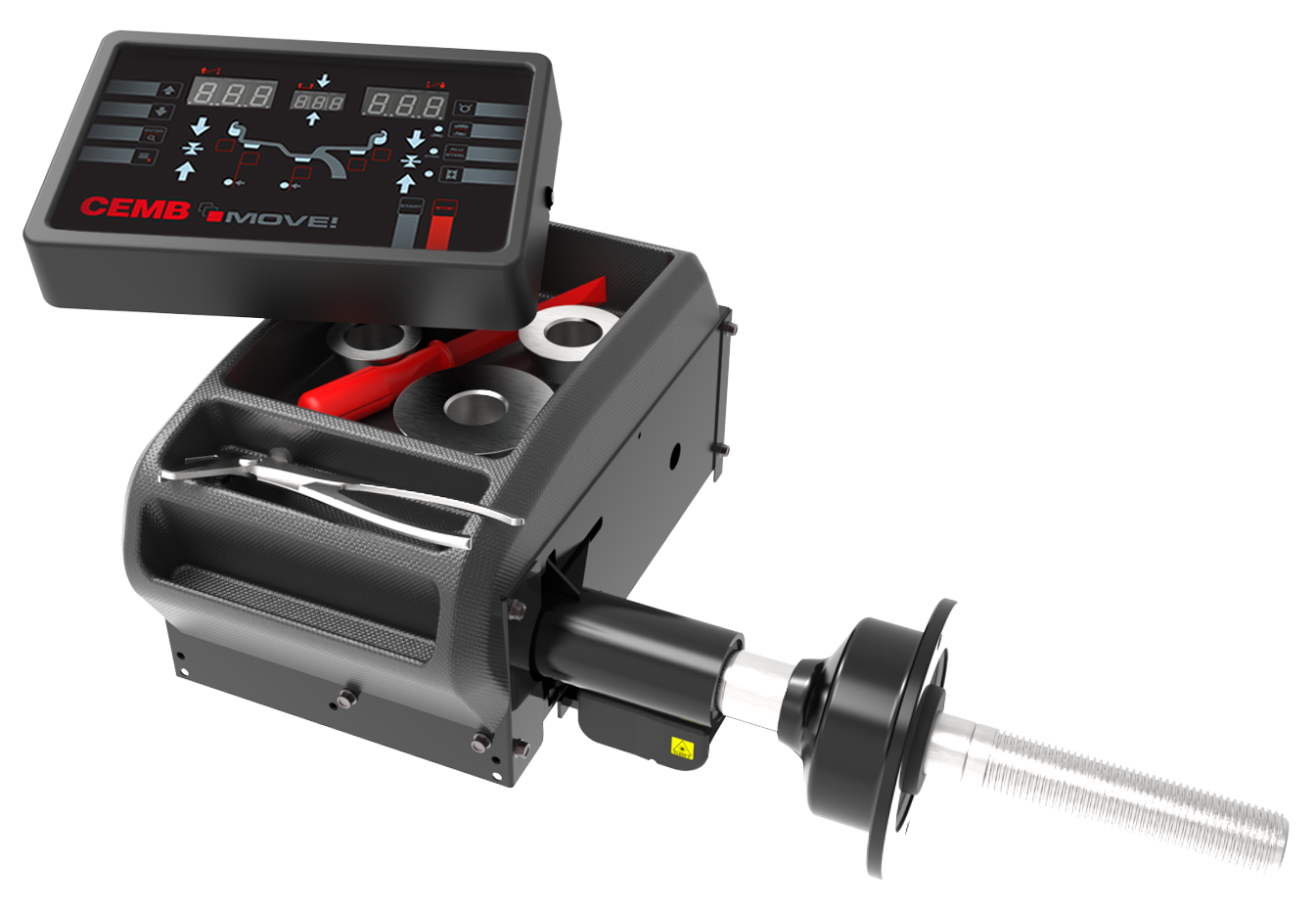

ER85 2-HIT: video wheel balancer with unique data input system

ER85 2-HIT: video wheel balancer with unique data input system

Description

CEMB extends the 2-hit technology to a new model in the range, providing a professional-grade product that is so user-friendly, it can be operated by anyone. The process of wheel balancing has never been more straightforward.

By manually moving the wheel, as shown on the monitor, the LASER SPOTTER, combined with a line laser, moves on the rim to measure its dimensions without using the gauge anymore. The same laser then indicates the exact point where toapply the correction weights, making the balancing process even more efficient.

LASER MATCHING - Line laser emitter which, together with the laser spotter, allows calculating the diameter of the rim.

PUNCH - The confirmation and transmission of the data acquired by the two lasers to the software occurs by lightly punching the tyre.

Key Features:

- OPB One Plane Balancing - Correction of both static and dynamic unbalance on one plane at once and with only one weight

- AutoAdaptive Mode - The new tolerance calculation system

- Sonar LA for automatic measurement of the wheel width

- EMS Sonar (option) - 1st Harmonic and Peak to Peak) Automatic and quick eccentricity measurement during the normal balancing cycle

- ALU-S Balancing mode - Adhesive weights on the internal rim planes with specific counterweight position indicator (position repeater)

- Tyre Set - The software indicates the best wheel positioning on the vehicle to get the best ride (conicity) and to minimize wheel vibrations (eccentricity) (option available only with EMS sonar)

- HubMatch - During the measuring cycle , the wheel’s “maximum eccentricity point” is detected and displayed on monitor, therefore allowing for its reduction during the re-mounting of wheel on vehicle (option available only with EMS sonar)

- Pneumatic wheel locking: Floor to floor time reduction / Extremely easy and quick to use / Very accurate wheel centering

- Automatic rotation and locking of the wheel in weight position

- Led light to illuminate the working space inside the rim

- VDD Virtual Direct Drive - Very quick and maintenance free measurement system