Celette Workshop Equipment

Celette Workshop Equipment

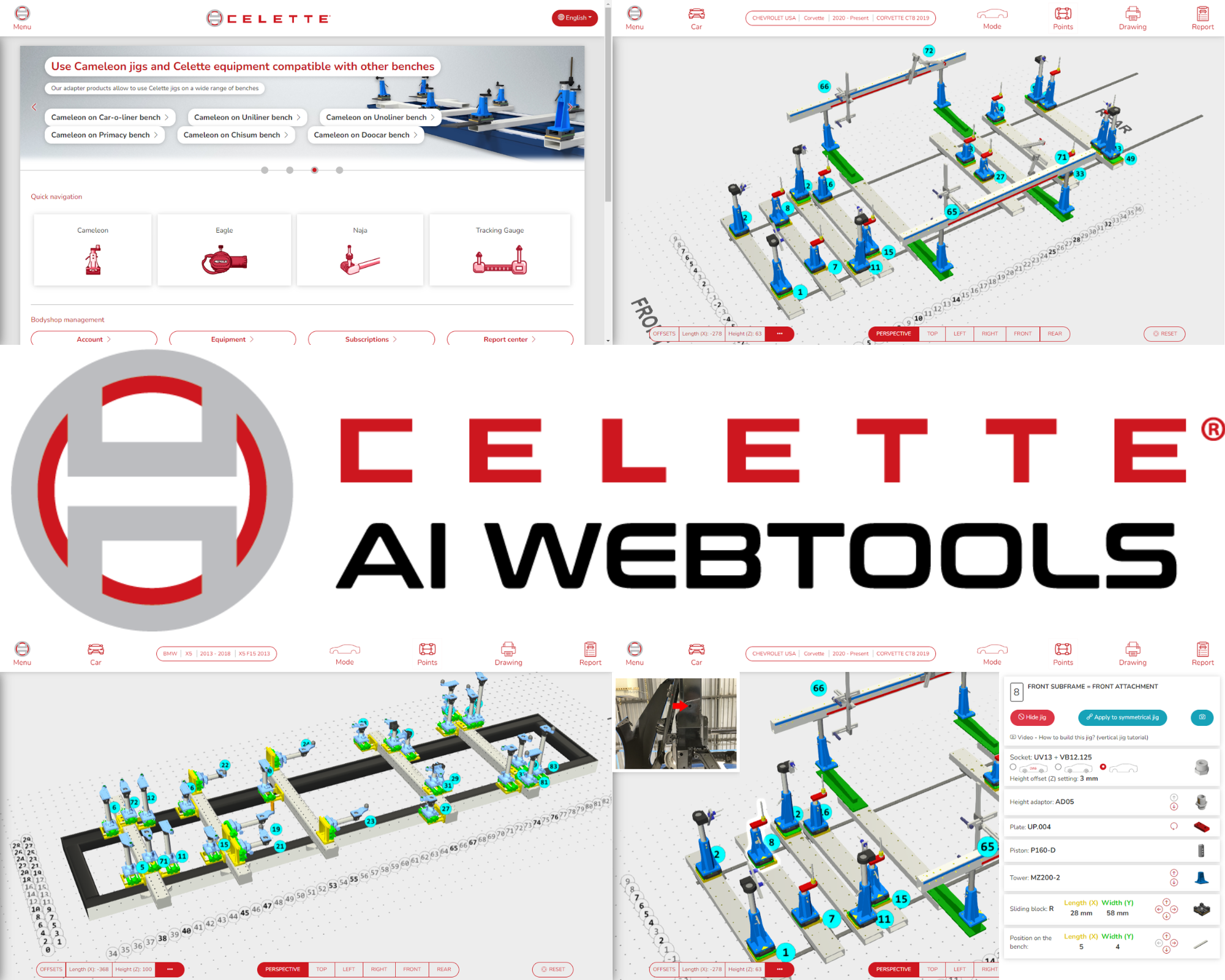

Description

Celette is a leader in the automotive bodywork sector, renowned for its comprehensive range of workshop equipment designed to meet the diverse needs of body shops. Our products are crafted with precision and innovation, ensuring top-notch performance and reliability. Here’s an overview of our key offerings:

**Benches**

Celette's benches are the cornerstone of any body shop, providing a stable and robust platform for vehicle repairs. Our benches are designed to accommodate a wide range of vehicles, offering versatility and ease of use. They ensure precise alignment and secure positioning, facilitating accurate and efficient repair processes.

**Universal Jig System**

Our Universal Jig System is an industry-standard tool that offers unmatched flexibility and precision. This system allows for the accurate positioning and holding of various vehicle components during repair, ensuring that all parts are perfectly aligned. Its adaptability makes it suitable for a wide range of vehicle models, enhancing the efficiency of the repair process.

**Electronic Measuring System**

Precision is crucial in automotive repairs, and Celette’s Electronic Measuring System delivers just that. This state-of-the-art system provides accurate measurements of vehicle dimensions, helping technicians identify misalignments and ensure that repairs are carried out to exact specifications. Its advanced technology enhances diagnostic capabilities and supports high-quality repairs.

**Floor System**

Celette’s Floor System is designed to integrate seamlessly into any workshop, providing a versatile and robust foundation for vehicle repairs. This system supports the use of various tools and equipment, offering a flexible workspace that can be adapted to different repair needs. Its durable construction ensures longevity and reliability in demanding workshop environments.

**Welding Equipment**

Our range of welding equipment is designed to meet the high standards required in automotive repairs. Celette’s welding tools are known for their precision, durability, and ease of use. They enable technicians to perform high-quality welds, ensuring the structural integrity and safety of repaired vehicles. Our welding equipment is suitable for various materials, including steel and aluminium, making it a versatile addition to any workshop.

Celette’s commitment to innovation and quality is reflected in our extensive range of workshop equipment. Each product is designed to enhance the efficiency, accuracy, and reliability of automotive repairs, ensuring that body shops can deliver the best possible results for their customers.