VTM GROUP, LTD

TURBO-BOOST-TEST Turbocharger Dynamic Calibrating & Testing Bench

Explore product

TURBO-BOOST-TEST Turbocharger Dynamic Calibrating & Testing Bench

Explore product

TURBO-BOOST-TEST Turbocharger Dynamic Calibrating & Testing Bench

Explore productDiscover more from us

About us

VTM Group manufactures balancing machines for turbocharger and driveshaft repair shops, dynamic balancing machines for crankshafts, flywheels, brake disks and drums.

VTM Group Ltd. is an advanced developer and manufacturer of balancing machines for various workpieces weighing from 0.03 to 40,000 kg, in any designs and size.

Our machines high productivity and universality allows to use in production and overhaul workshop.

Equipment and tools are offered only in accordance with specifics of your business.

Any employee of any qualification level can easily learn operation and maintenance skills.

THE MAIN LINE OF BALANCING MACHINES

Turbocharger balancing and repair equipment.

- TURBO-BOOST-TEST Turbocharger testing bench

- SBR-10 Turbocharger VSR balancing machine

- GEOMET-2000 VNT Turbo Flow bench

- ATP-1000 Turbocharger actuator testers

- Balancing machine for the turbo rotor BVI-03-10T

- Balancing machine for the CHRA turbocharger DBST-10

Driveshaft balancing and repair equipment

- Driveshaft balancing machine 150kg

- Driveshaft balancing machine 200kg

- PRK-2 Manual press for stacking u-joints

- P1515 Hydraulic press 15t

- PRK-7 Assembly and welding bench for cardan shafts

Dynamic balancing machines for various automotive components

- Balancing machines for crankshafts

- Balancing machines for DMF, Flywheel

- Balancing machines for torque converter

- Balancing machines for brake discs

DPF cleaning machine

POSEIDON-1000 Professional equipment for regeneration

of DPF filters and catalysts of passenger and commercial vehicles.

VTM GROUP - THE TRUSTED EXPERT IN THE WORLD OF BALANCING

More than 500 enterprises in the world work on our machines. Over the past 15 years, we have produced more than 1000 and modernized more than 400 balancing machines with the installation of modern digital electronics of our own production.

Our machines operate in Germany, England, Bulgaria, Netherlands, Slovenia, USA, Latvia, Poland, Kazakhstan, Armenia, Romania, UAE, South Africa and other countries.

Visit our booth for a machine presentation!

Our product groups

Downloads

Keywords

- driveshaft balancing machine

- turbo flow bench

- turbolader strömungsprüfstand

- turbolader auswuchtmaschine

- turbocharger balancing machine

Our Products

VSR Turbocharger Balancing Machine

SBR-10 professional specialised equipment for high-speed balancing of assembled turbo cartridges. Equally useful for car and truck turbocharger.

The machine was designed for entry level turbocharger repair workshop, including medium re-manufacturers. It solves a wide range of tasks that repair centres face on a daily basis.

The SBR-10 simulates the same testing and balancing conditions as the turbocharger on the vehicle, this allows the quality of the repair to be guaranteed. It also allows checking turbocharger for oil leakage.

HIGHLIGHTS

- Mounting the cartridges on their standard surfaces (as on the engine) allows the installation of almost all turbochargers.

- Wide range of accessories and adapters for installing any kind of turbos

- Includes adapters for installing turbochargers with bottom oil inlet and reverse rotation turbines

- The turbocharger rotation and measurement is automatic. The cycle includes acceleration to maximum speed, measurement during the cycle, and air shutdown.

- Emergency shutdown is provided in case of extreme vibration increase, which prevents cartridge destruction even in case of assembly errors

- Automatic cycle allows to carry out vibration measurement in a short and sufficient period of time.

- Vibration measurement of the turbocharger housing - up to a value of 10G, which 2 times better than other analogs.

KEY FEATURES

- Car and truck turbocharger balancing

- Any turbocharger installation

- All type turbocharger adapters

- Reverse rotation adapters

- Balancing speed up to 300 000 rpm

- Fast oil heater and temperature regulation

- 3-stage oil filtration

- Real-time unbalance measurement

- Automatic cycle turbocharger balancing

- An industrial fanless touch screen pc control system

- Access to self-editing of the data base

- Creation and printing of reports on turbocharger balancing

Visit our booth for a machine presentation!

TURBO-BOOST-TEST Turbocharger Dynamic Calibrating & Testing Bench

The turbocharger boost test bench allows for professional turbocharger calibration and performance evaluation. The test bench can be used in turbine tuning and refinement, in the manufacture of hybrid turbines, to test changes in turbine performance after tuning.

Our test benches are advanced systems for turbocharger tuning and testing in dynamic mode. They provide turbocharger testing under near realistic operating conditions, ensuring full process control and detection of any potential problems, including oil leaks.

The specialized software built into our equipment features sophisticated calculation algorithms that provide an accurate assessment of turbocharger performance after testing. All process information is displayed in real-time in graphical and digital formats, providing operators with the best possible visualization of the data.

During testing, graphs are automatically generated to illustrate the relationship between boost and turbocharger inlet and outlet flow rates. This allows for in-depth turbo diagnostics to accurately determine the condition of each turbine component. Graphs can be analyzed easily and efficiently thanks to the ability to compare current data with reference values and results of previous tests.

The test bench database contains more than 2000 test plans and is ready to be expanded, which ensures the possibility to work with a wide range of turbochargers and their analogs. Our test benches are a reliable and powerful tool for quality and efficient diagnostics and tuning of turbochargers of any type.

Turbocharger Actuator Testers & Programmers

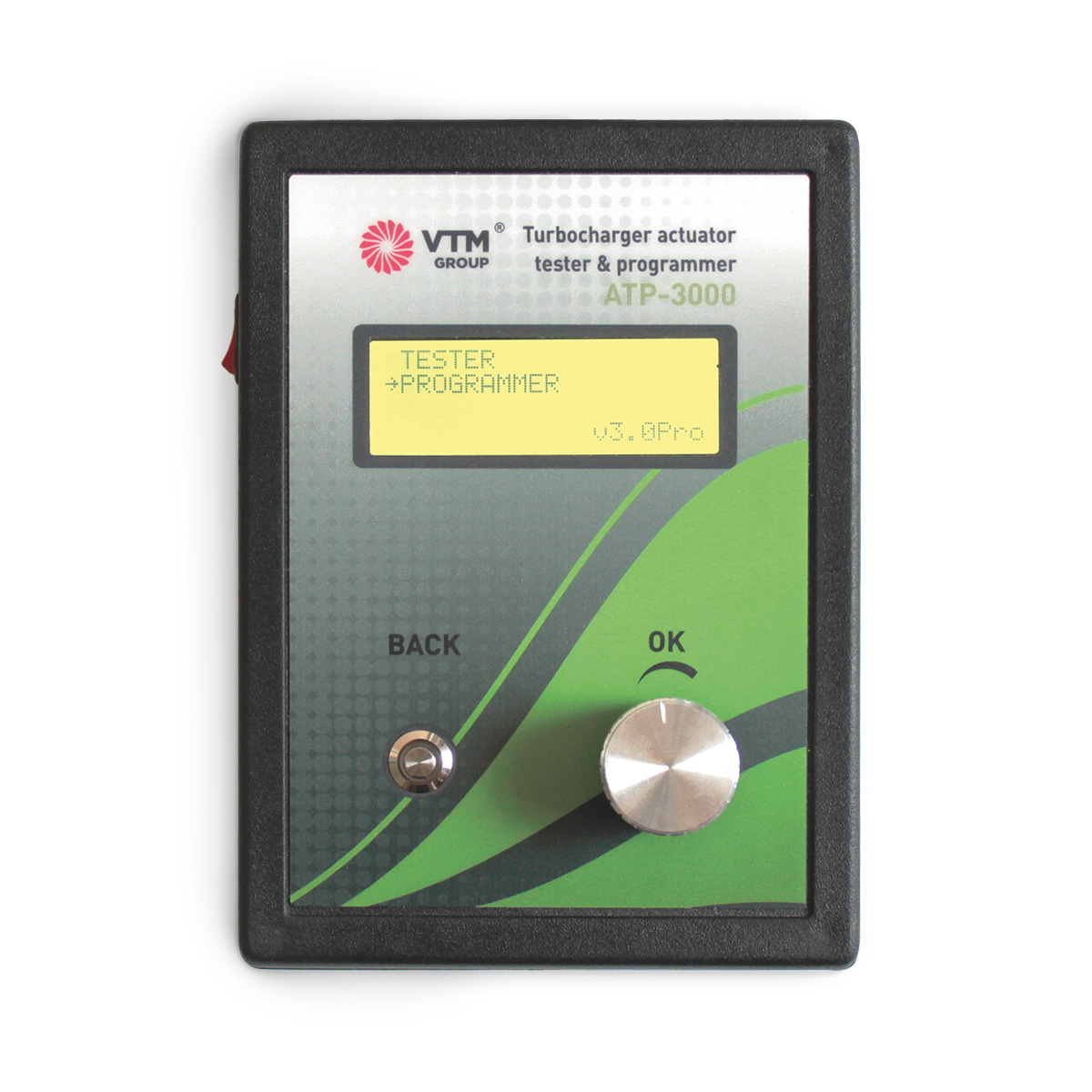

ATP-3000 Tester & programmer for diagnostics of passenger car turbocharger actuators

The tester checks the functionality of the actuator as a whole and its individual elements such as the position sensor and servomotor. Separate diagnostics of each element allows you to accurately determine the condition of the turbocharger actuator and detect a problem, if one exists.

The ATP-3000 is easy to use and allows you to quickly check the condition of the actuator and its components. This has made it an effective tool for monitoring the functionality of actuators.

Tester can be successfully used in companies engaged in turbocharger repair, as well as in car repair services offering a wide range of repair works to determine the cause of turbocharger malfunction. It is also suitable for companies supplying electronic actuators.

HIGHLIGHTS

- Testing of electronic actuators for turbochargers

- Programming of HELLA electronic actuators

- Programming (adaptation) of SIEMENS electronic actuators

- Testing of 12V DC motors up to 2A

- Testing of boost solenoids used in pneumatic systems

- Testing of electronic and pneumatic actuator position sensors

- Works with all common types of actuators and similar in principle of operation.

- Communication protocols: PWM, CAN, ADC, SENT.

KEY FEATURES

- Protection of the device by current 2A for 3 seconds

- Automatic detection of DC motor polarity inside the actuator

- Tooltip for color-coding the cable to the selected actuator type

- Display position sensor readings as a percentage

- Display of additional parameters of HELLA programmable actuators: firmware number, programmed angle value

- Portable version for testing directly on the vehicle

- USB control of actuators, when working together with the software of GEOMET-2000 turbo flowbenches

- Regular updating of the tester firmware

Visit our booth for a ATP-3000 life presentation!

BVI-03-88 Driveshaft Balancing Machine

Balancing machine for professional repair of cardan shafts up to 200 kg.

The hard-bearing machine is adapted for heavy cardan shafts of trucks and special machinery. The high sensitivity of the supports allows also high-quality balancing of cardan shafts of passenger cars.

The machine is designed for balancing cardan shafts in the facilities of cardan repair workshops. The machine can be quickly reconfigured for balancing a large amount of single cardan shafts of various designs, as well as for the production of small batches of shafts.

TWICE faster than your machine.

If you can balance in 2-2.5 times faster, then this is your real competitive advantage.

This balancing machine is majored to balance the shaft not only qualitatively, but also quickly.

HIGH PERFORMANCE FEATURES

- Balancing of 2, 3 and 4-support cardan shafts

- Shaft length up to 5200mm, weight up to 200kg

- Cardan installation in 1 minute

- Machine is operated by one worker

- Standard set of adapters - Installation of 80% of cardan shafts

- Three ways of fixing the center bearing

- Hard-bearing type machine - safe balancing of shafts with large initial unbalance

- Sliding tailstock spindle - quick changeover, comfortable operation

- Safety bracket with clamp for quick installation

- Measurement in all planes at one time

- Calibration of the machine by the operator

- Displays imbalance in real time

- Create and print reports

Visit our booth for a machine presentation!

9D715US Crankshaft Balancing Machine

9D715US balancing machine is a high-precision equipment specially designed for balancing crankshafts in engine overhaul shops.

The machine is capable of balancing various types of crankshafts, balancing crankshafts complete with flywheel, clutch and pulley, including V-type crankshafts with attached bobweights.

The drilling module allows unbalance correction by drilling counterweights directly on the machine.

With the 9D715US balancing machine you get a reliable and powerful tool for high accuracy and quality crankshaft balancing.

HIGHLIGHTS

Thanks to its innovative technology and high performance, it solves the following tasks:

- Measuring and correcting large initial crankshaft imbalances.

- The narrow support rollers allow the crankshaft to be balanced complete with flywheel and pulley

- Compact size of the belt drive eliminates the difficulties of balancing with bobweights attached to the crankshaft

- An integrated drilling unit mounted on its own guides increases the productivity of the balancing operation

- The software function for converting unbalanced mass to drilling depth ensures accurate and efficient unbalance correction directly on the machine.

MEASUREMENT AND CONTROL

- We make balancing easier - the main advantage of our balancing machines.

- The balancing process is displayed in real time and the unbalance behaviour of the rotor is monitored on the screen to achieve the best possible result

- The maximum accuracy of the machine at any moment of operation, the set-up and calibration of the machine is carried out by the operator himself

- Free from the influence of external vibration factors on the measurement result, it has a high degree of protection against various types of interference

- Easy to learn working skills and maintenance for any employee.

With the 9D715US balancing machine you get a reliable and powerful tool for high accuracy and quality crankshaft balancing.

Visit our booth for a machine presentation!