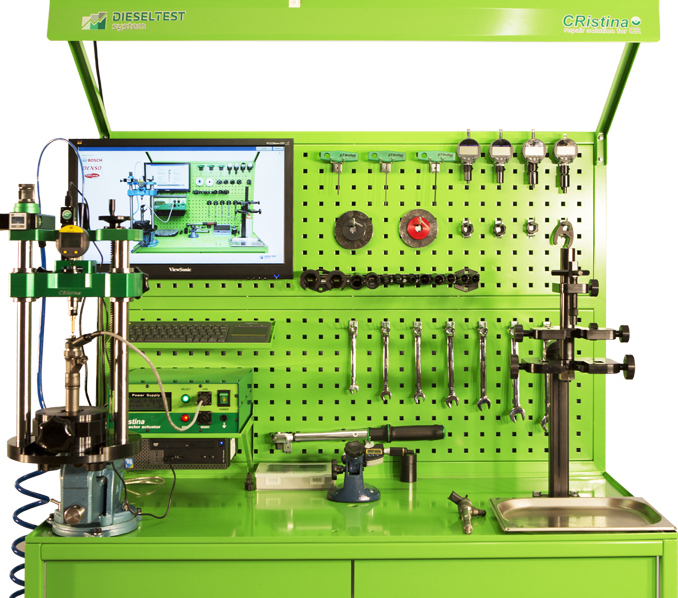

Triumf, Test bench for testing CR injectors

TRIUMF benches are manufactured with the possibility of retrofitting with a hardware and software complex for encoding Bosch, Delphi, Denso injectors. To encode the Delphi injectors, a device is additionally installed, which allows to create a vacuum in the backleak line of the injector. The set of the vacuum creating device is a gear pump, a venturi tube and an electric motor. The device is installed on the bulkhead, which is located in the lower part of the bench above the cooling unit.

As a working fluid in the test bench, a test liquid of ISO 4113 standard is used. The source of high pressure is a high-pressure fuel pump (HP pump), which has a drive from an asynchronous motor of 4 kW, 1500 rpm. As a feed pump, a gear pump is used, integrated into the injection pump housing and having the same drive.

The vacuum creating device is mounted on a separate gear pump, which is located at the bottom of the bench above the cooler.

For thermostabilization of the test liquid in the tank, the following applies:

- two radiators with forced air cooling for the backleak line from the injection pump and the -backleak line from the pressure accumulator (rail).

- independent cooler with air heat exchanger.

- 1000 W tubular electric heater

Working pressure up to 1800 bar. It is possible to increase the working pressure to 2400 bar.

The bench has an electronic measuring system with the possibility of simultaneous testing of 4 injectors.

The program with test plans is included in the set of delivery. Software updates, including new test plans, are published twice a year and are provided free of charge.

![]()