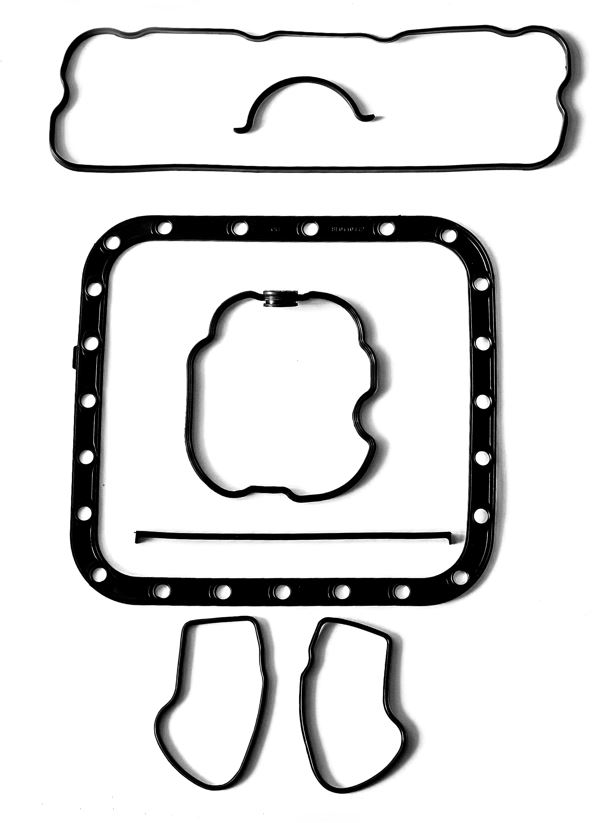

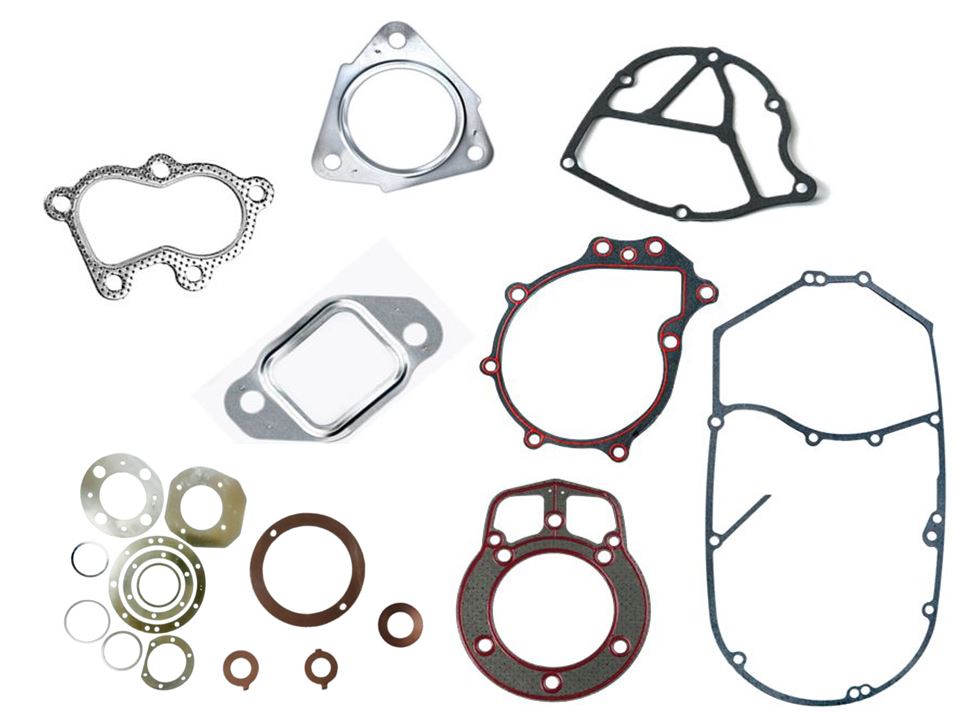

Secondary Gaskets:

Secondary Gaskets:

Inlet/Exhaust Gaskets in composite materials and in NBR & Viton rubber coated with embossment.

Flange Gaskets with embossment and spot-welding of 2/3/4 layers in stainless material.

Silencer Gaskets as Copper rings with filler inside.

Rocker Cover Gaskets and Sump Gaskets.

Flat and soft & secondary gaskets.

Cork Gaskets:

Our cork gaskets are expertly designed to establish a robust, maintenance-free seal. The cork particles embedded within these gaskets promote easy compression, ensuring a secure and leak-free sealing solution. Their durability extends to high-vacuum and high-temperature conditions while maintaining their compression. Explore our extra-thick cork valve cover gaskets to optimize valvetrain-to-cover clearance.

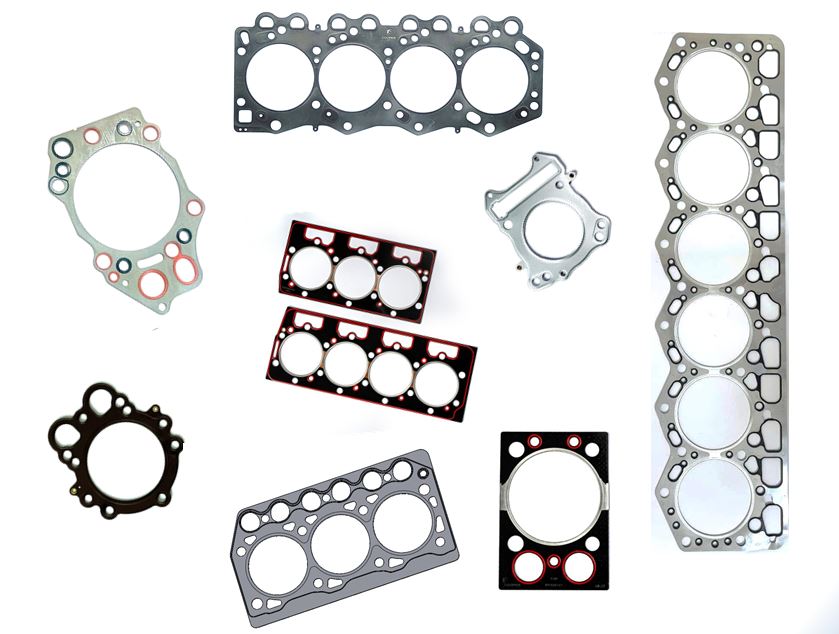

Fiber Gaskets:

Fiber gaskets exemplify remarkable tensile strength and exceptional blowout resistance. Their corrosion resistance makes them a suitable choice for applications involving racing fuels and alcohol. Eliminating the need for retorquing, these gaskets ensure effortless and dependable performance.

Washer & Shims: Precision at Your Service

Discover our extensive range of washers and shims, tailored for diverse applications and materials, including Ferrous and Non-Ferrous options, as well as Red Fiber materials. Our comprehensive selection enhances functionality and reliability in various applications, ensuring precision at its best.

Graphite Gaskets:

Gaskets featuring a graphite core excel at dissipating heat, effectively guarding against gasket burnout. They offer exceptional compressibility, high-temperature endurance, and resilience to challenges like creeping, cold flow, or brittleness. Graphite coatings facilitate gasket movement without causing damage.