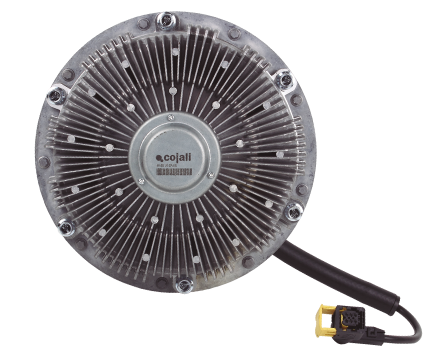

Cooling Systems

Description

Cojali standard. Our cooling systems adaptable to the main brands of truck, bus, light vehicle, passenger car, agricultural machinery and construction machinery are manufactured under the most demanding quality standards, as the ISO 16750, and they certify a long useful life, as well as the optimisation of the vehicle performance.

Furthermore, we have a specific line equipped with the necessary technology to manufacture components that meet the Euro 6 anti-pollution standard, where the cooling system presents much more demanding requirements. Together with our R+D+I team, made up of more than 100 industrial engineers, we insist on developing products that contribute to the optimal and sustainable operation of the components patenting our technology.

Know our cooling system in depth. Choose Cojali brand.

Efficiency and environmental care

The system of viscous clutches with fan is specially designed to be as energy efficient as possible in the vehicle cooling system. In Cojali we develop this system taking into account the cooling needs in any work condition, optimising the air flow generated by the fan. In this way, the fan speed is reduced in circumstances where the engine temperature is low, reducing the fuel consumption and noise level and thereby minimising the environmental impact.

High reliability and long useful life

In Cojali we guarantee high reliability and long life in all our products for cooling systems. The viscous clutches manufactured under the Cojali brand are devices that have no components in contact, therefore its wearing is reduced to the maximum. This is one of the main reasons why the viscous clutches present a huge advantage regarding other devices with the same functionality, as for example friction clutches of viscous clutches of the competence. Furthermore, our Quality Department implements a thorough control of the production process, showing special interest in ensuring that the product is finished in optimal conditions for its function.

Flexibility and product variety

We manufacture a wide range of clutches and fans for commercial vehicles, as trucks and buses, agricultural vehicles, construction machinery and light vehicles. We currently cover the 95% of the European market and are growing in the American and Asian market. Within the product range, there are clutches with different activation types and formats, and plastic fans with different characteristics. Furthermore, in Cojali we offer a lot of flexibility in the production of small amounts of product, thanks to the innovative design of our production line, that allows the manufacture of any clutch or fan reference available in the catalogue, without the need of big changes, saving in production costs.

Product customisation ability

Our Engineering Department develops each clutch and fan reference taking into account the specifications of each application. In Cojali we optimise the design to achieve a final product with the best offer in quality and price. Furthermore, we adapt to any product requirement for new application requests, offering specialised technical support if needed.

Quality control of finished product

The 100% of the components for cooling systems manufactured in Cojali undergo a thorough quality process to guarantee that the product specifications are met before its installation in the vehicle. In the case of the clutches, they undergo a specific test for each reference known as “end of line test”, that consists in simulating in a test bench the behaviour of the clutch in different operation phases. In the case of the fans, the 100% undergoes a balance test, to guarantee the stability of the fan-clutch system.