Description

**Product Overview**

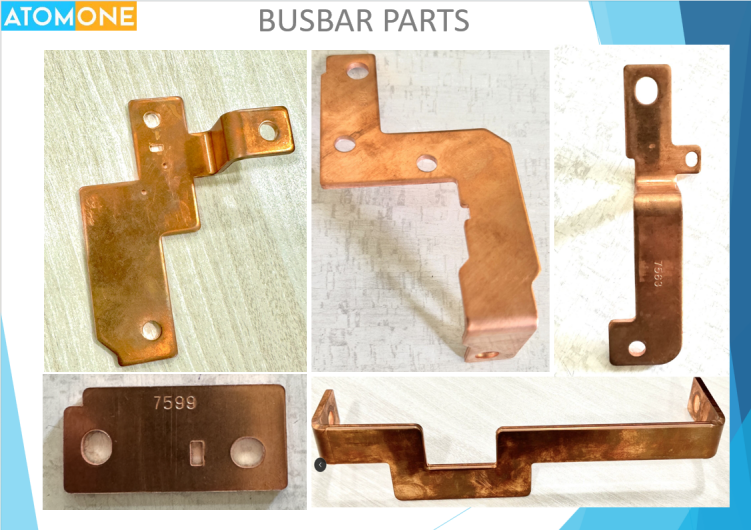

Busbars are critical components used in electrical power distribution systems. AtomOne Technologies specializes in the design and manufacturing of high-conductivity copper and nickel busbars. These busbars are engineered to provide efficient power transfer with minimal energy loss, ensuring reliability and performance in various industrial applications.

**Features and Benefits:**

1. **High Conductivity:**

- Manufactured from premium-grade copper and nickel, our busbars offer excellent electrical conductivity, ensuring efficient power transfer.

2. **Durability:**

- Designed for robustness and longevity, these busbars withstand harsh industrial environments and demanding applications.

3. **Custom Designs:**

- We offer tailored solutions to meet specific customer requirements, ensuring perfect fit and function in any application.

4. **Precision Engineering:**

- Utilizing advanced manufacturing techniques, our busbars are crafted to precise specifications, ensuring optimal performance and reliability.

**Applications:**

- Electrical Power Distribution Systems

- Industrial Machinery

- Automotive Electrical Systems

- Renewable Energy Systems

- Electrical Panels and Switchgear

**Manufacturing Capabilities:**

- **Advanced Machining Equipment:**

- CNC turning and VMC machines for high-accuracy busbar production.

- Custom machining capabilities to accommodate unique design requirements.

- **High-Quality Materials:**

- Use of top-grade copper and nickel to ensure superior performance and longevity.

- **Rigorous Testing:**

- Comprehensive quality control processes including surface roughness testing, plating thickness testing, and precision measurement to ensure each busbar meets stringent industry standards.