Educational diesel engine model with CR EDC – 15 fuel supply system

Educational diesel engine model with CR EDC – 15 fuel supply system

Beschreibung

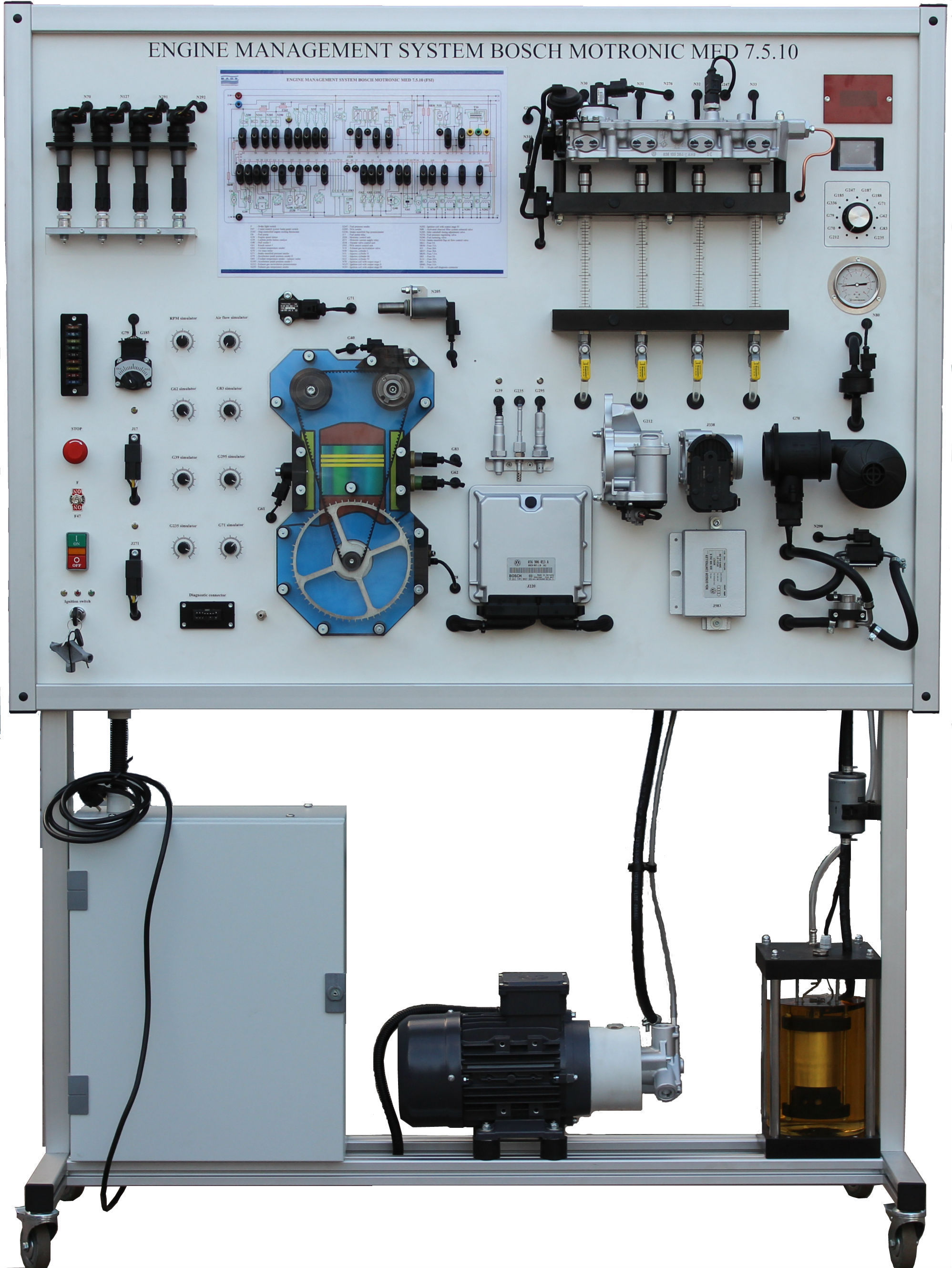

Self – contained, fully operational diesel engine model is installed in a mobile frame. This training engine is specially designed to demonstrate Common Rail diesel injection system and operational structure. Educational training engine is based on original (refurbished) components of Renault vehicle with functional engine control system Bosch EDC 15. Training engine is a great educational tool that allows students to learn the structure of engine and its components, power supply system, cooling system, engine control system. It also allows to study components and operation modes of the engine control system, perform various measurements, tests and other diagnostic procedures.

Technical specifications and functions

- Educational functional engine model with CR fuel supply system, instrument cluster cooling system, power supply system and the exhaust system;

- Completed with safety removable panels to protect against hot and rotating parts;

- Electrical wiring diagram with built – in banana plug jumpers for measurements and simulation of system fault codes;

- Possibility to simulate more than 20 faults by disconnecting Banana plug jumpers;

- After removing safety panels clearly visible the engine with external components, easy access to the engine and its components for service and maintenance;

- Integrated engine emergency stop button;

Diagnostic and measurement Oscilloscope/multimeter

- System’s parameters are measured by connecting to the banana connector;

- Possibility to measure electrical signal parameters of each system component (such as sensor or actuator);

Control unit diagnosis

- Diagnosis through OBD 16 – pin diagnostic connector;

- Electronic control unit (ECU) identification;

- Reading/erasing fault codes;

- Displaying the operating system parameters (live data);

- Activating the actuators (Depends on the control unit);

- Control unit coding/configuration;

Other

- The stand has a closed structure – internal wiring is not visible; Instrument cluster, measurement and fault simulation panel is integrated in a closed aluminum frame construction;

- Dimensions approx.: (HxLxW) 1550x1000x1200mm;

- Weight (netto) approx.: 350 Kg;

- Made in Lithuania;

- CE certificate;

Optional accessories

- Examination console for 10 hidden fault simulations;

- Vacuum gauge;

- Low pressure gauge in the fuel supply line;

- Automotive oscilloscope;

- OBD diagnostic scan tool;

- Diesel smoke meter;

- The exhaust extraction system;