KINERGO UAB

Beschreibung

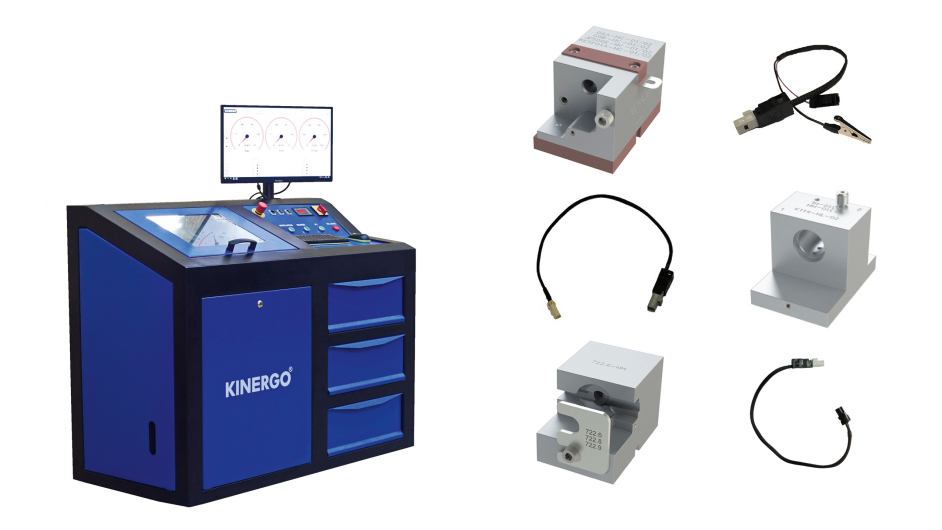

Solenoid test machine STM-K

This test bench is designed to test the operability of solenoids from various manufacturers.

The following tools are used:

- control system for the amount of current flowing through the solenoid coil;

- high-precision pressure sensors for obtaining open graphs and hysteresis loops;

- a flow meter that controls the flow of liquid through a solenoid.

Advantages:

- KINERGO controller for simulating signals of electronic automatic transmission units. Maintaining preset constant conditions during the test using unique soſtware and visual

demonstration; - the test process is optimally adapted to the specific tested solenoid;

- fast and equal preheating of the working fluid;

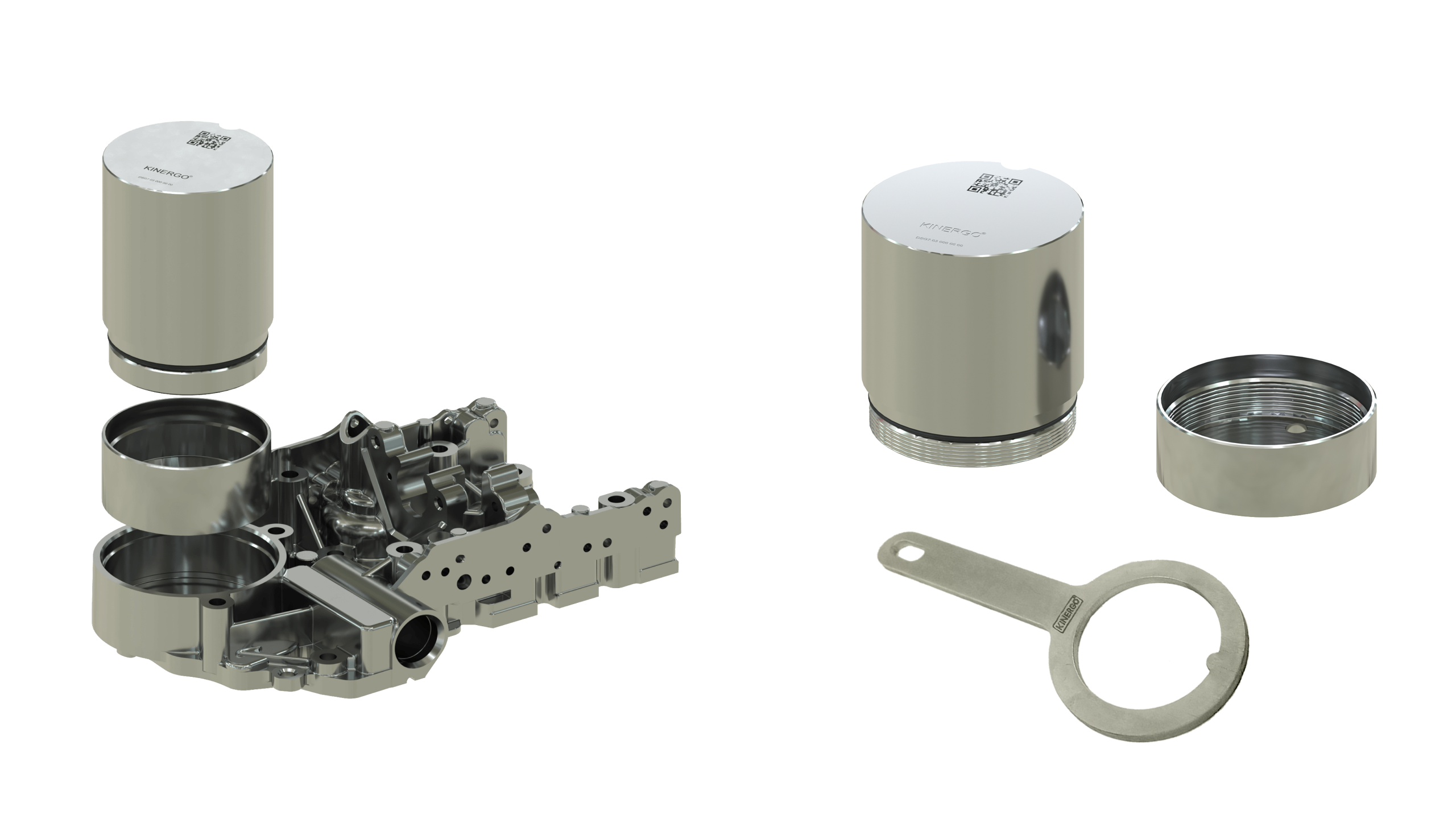

- more than 80 special adapters;

- intuitive, updatable soſtware.

To ensure maximum ease of use, KINERGO has developed an assortment of special

adapters for solenoids, which allows diagnostics of products of most popular brands.