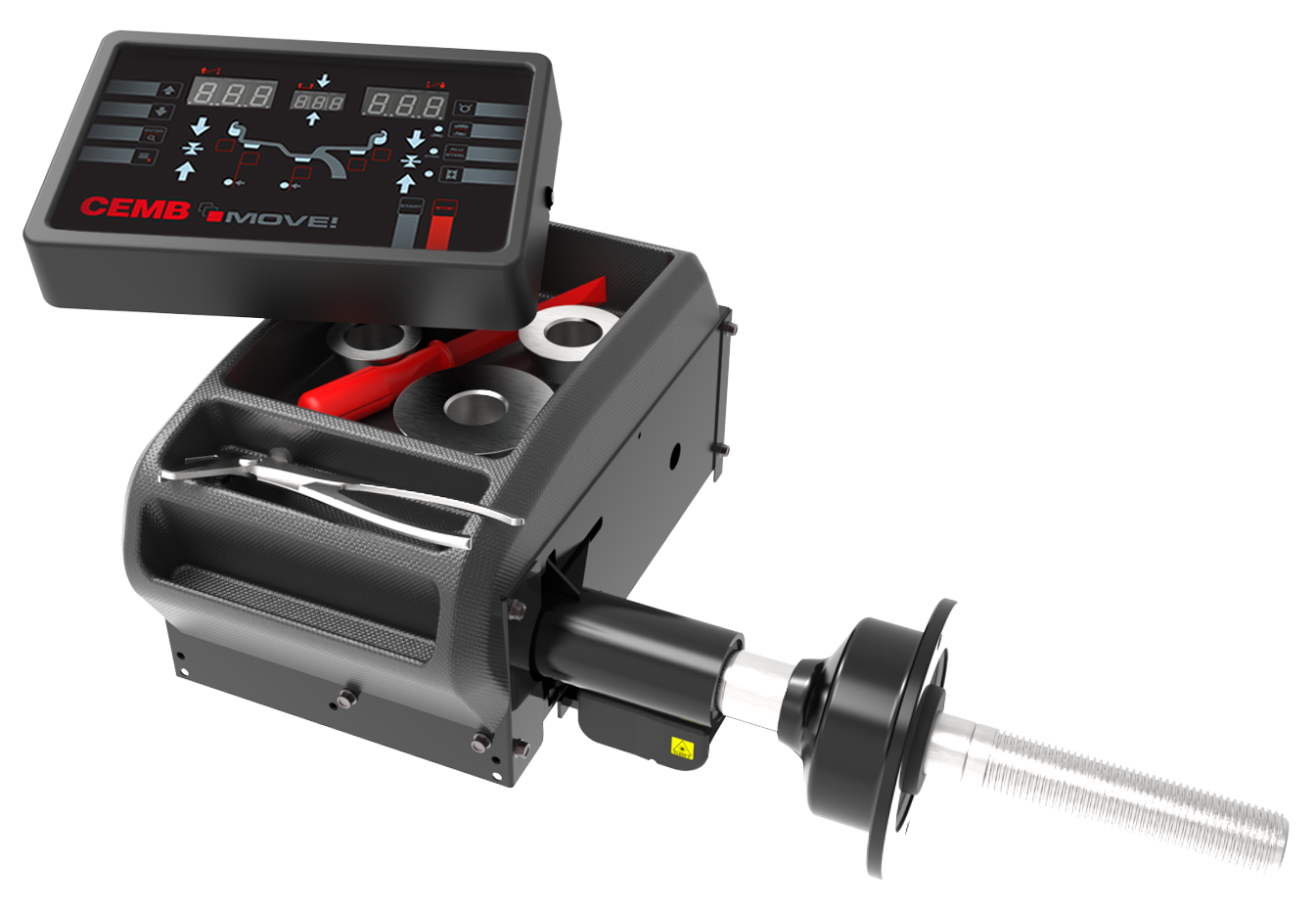

Leverless tyre changer with dynamic movement

The latest generation new super-automatic tyre changer for car wheels, SUVs and commercial vehicles up to 30”. The new dynamic tool, thanks to its geometry, creates an angle between rim and bead that allows considerable reduction of bending on the tyre and of contact with the rim. The reinforced structure, the super-performing clamping, ergonomics, and intuitive controls ensure operational speed, effortless work and make it usable at 360°.

Dynamic Tool - Patented

With Dynamic tool, CEMB exceeds the limits of traditional LeverLess systems which normally simulate the action of a manual lever that acts on the rim edge through forced extraction of the tyre bead. D-tool is a dynamic system that moves in two directions: axial and radial. The front lever engages the tyre bead which is moved away from the rim edge, while the rear lever keeps it firmly guided and then it releases it on the external edge during disassembly and, inside the rim, during assembly.

- engagement with the bead is ensured by the special plier-shaped tool which then maintains

- its correct position for the entire duration of the assembly/disassembly process, with no risk of slipping

- it reduces the stress on the tyre limiting its wear and tear

- the contact-free movement prevents scratching the rims

- time-saving and limited intervention of the operator, if not in initial phase

- no need to use additional tools with subsequent reduction of effort

- easy to use and reduction of maintenance costs

- reliability and safety

Combined bead removal

Combined bead removal thanks to the two roller arms and the roller feed movement. The lower roller is always collinear with the assembly/disassembly tool. The upper roller is always tangent to the rim centre. Both rollers can be operated using the dedicated advancement pushbuttons in automatic penetration. The arm of the lower roller is built in the main structure of the frame, making it particularly sturdy and able to exert an even more effective pressure to help extracting the lower bead of the tyre.

Central post

Central post with electric translation movement to ensure greater positioning accuracy. Obtained from a cast iron casting process that makes it exceptionally solid even in the presence of the most extreme torsional stresses, it guarantees perfect and safe locking of any type of rim.

Pedal-operated inflator

Pulse inflation pedal with 4.2 bar pressure limitation (60 PSI).

Motoinverter

Motor controlled by the new motoinverter system with progressive speed variation. Rotation speed from 0 to 16 rpm. The inverter board is installed on the machine, away from the motor to prevent vibrations and overheating. Low energy consumption at rest (smart stand-by). High reliability and protection, with automatic alarm reset which brings the pedal to resting position (no power interruption is required). Low energy consumption ensured at rest (smart stand-by). Rated consumption occurs only during use.

Simple and intuitive controls

Intuitive and complete multi-function control console to easily operate all work instruments. Everything is close at hand to ensure perfect ergonomics in movements with any type of wheel: ideal for all operators.

Bead pressing arm

Bead pressing arm, with adjustable working height, that follows the rotation of the tyre to facilitate the assembly operations of UHP or run-flat wheels.