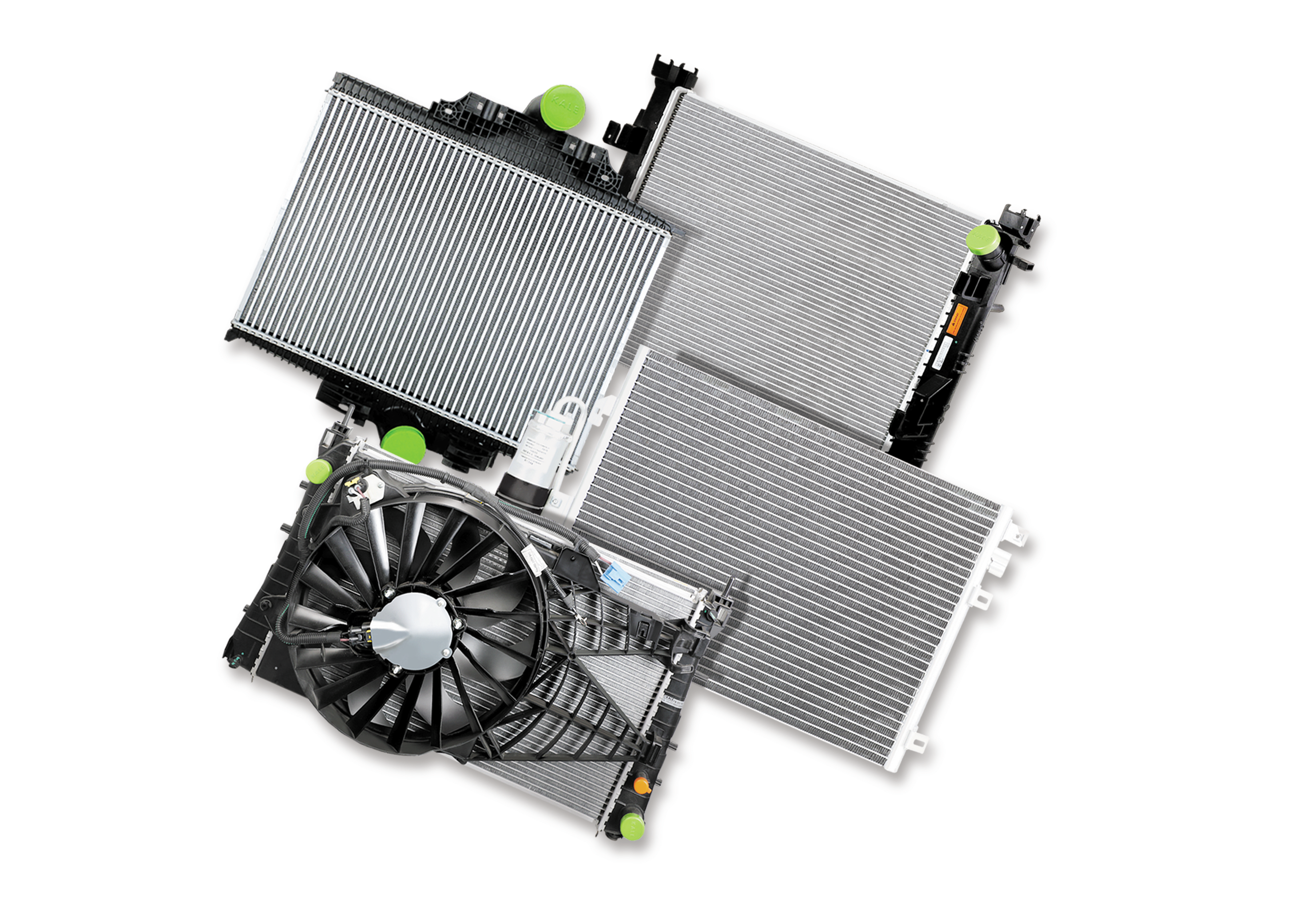

MesseneuheitINTERCOOLERS

INTERCOOLERS

Intercooler, also known as charge air cooler, principally functions as an air cooling heat exchanger. Generally fitted with the turbo charged engines, intercoolers have been mainly utilized in trucks, buses, tractors and high performance vehicles. By the mid 1970's, intercoolers were first mounted on the turbo charged engines in a limited way. By the utilization of intercoolers, harmful fuel emissions are reduced significantly whilst engine performance is boosted and fuel economy is improved. This function is achieved by the reduction of air inlet temperatures from 120 °C to 200 °C while passing through the turbo charger and bringing it down to the level of an air outlet temperature, which is approximately + 40 °C above the ambient temperature for Euro I engines , + 25 °C for Euro II engines and + 15 °C for Euro III engines.

And today due to new environmental regulations on fuel emissions, particularly on heavy truck, bus and other commercial vehicles , vehicle manufacturers are required to install intercoolers with Euro series engines.

KALE INTERCOOLER is designed and manufactured to provide;

- High engine performance

- Fuel efficiency

- Improved torque power

- Reduced fuel emission

- Compatibility with Euro series green engines.

With the employment of an intercooler, exhaust emission is improved, engine efficiency is increased, fuel consumption is reduced. These improvements are achieved by means of cooling the air intake and lowering its thermal stress before allowing it to go thorough the engine.

At the outlet of turbo charger , air temperature rises up to 200 C°. Air enters into the intercooler and cools down to the level, which is approximately + 40 °C above the ambient temperature. Then cooler air enters into the engine again.

Manufacturers have been calling these air coolers with different names such as charge air cooler , intercooler . However air coolers are pricipally mounted in between the turbo charger and the engine, which is making the term INTERCOOLER widely accepted in the industry.