Automatic angle mincers WW with Singrise cutting cyllinders

Automatic angle mincers WW with Singrise cutting cyllinders

Ekomex-Pilsniak Spólka z Ograniczona Odpowiedzialnoscia Spółka Komandytowa

Description

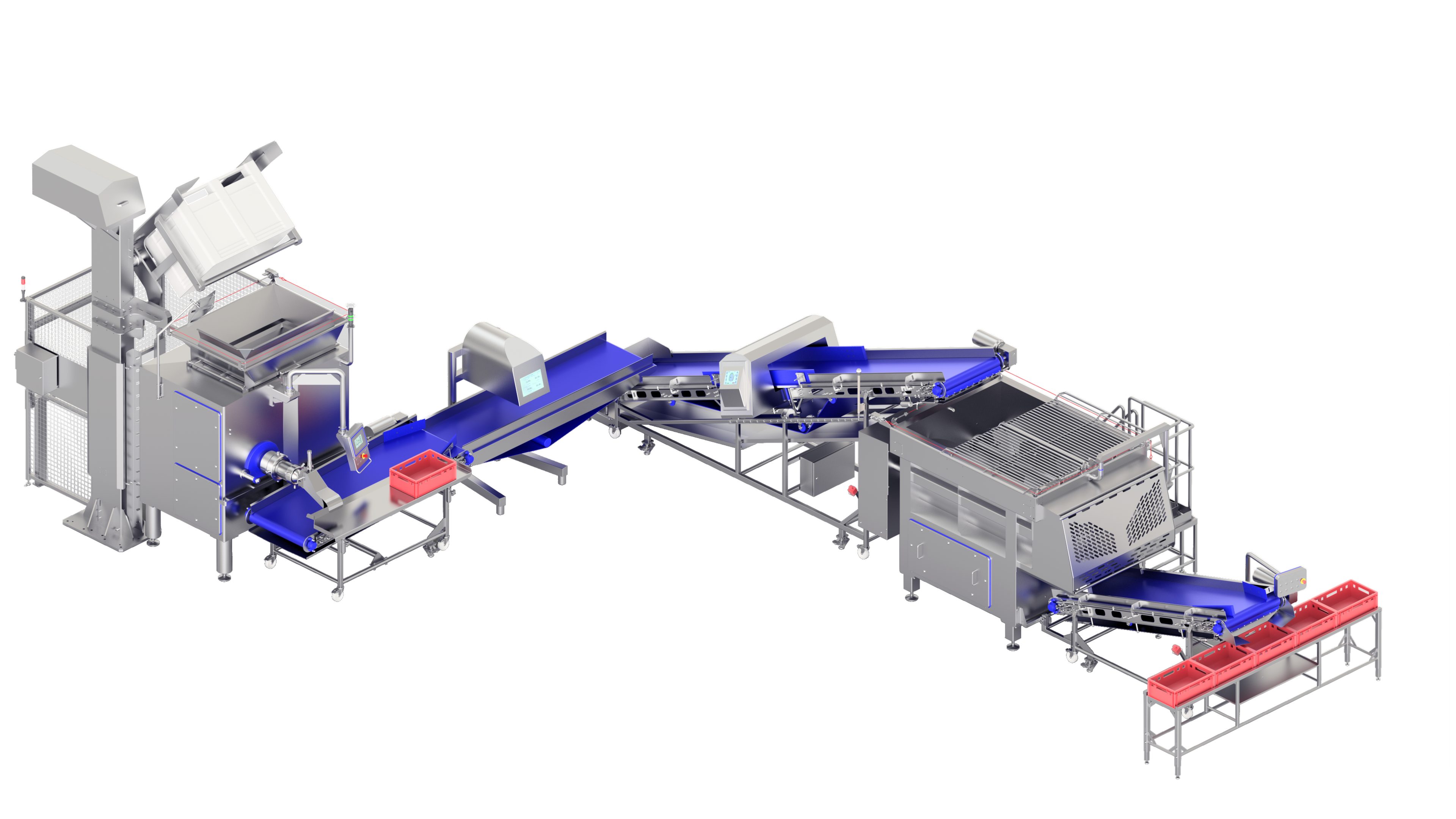

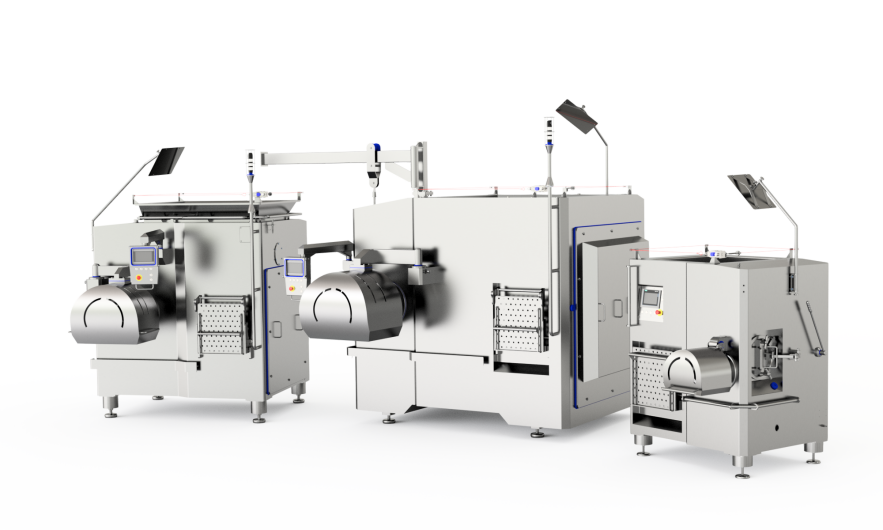

For grinding, mincing and cutting fresh and frozen raw materials for particular structure. Designed especially for grinding fresh and frozen meat in meat processing plants.

It is also effective in case of other food products in medium, large and industrial poultry, fish, cheese, vegetable and fruit processing plants as well as factories manufacturing petfood and convenience food. High-tech industrial machines that are strong, efficient and versatile.

Machines available in models WW-130, WW-160, WW-200, WW-280, WW-300 They can work with standard sets of cutting tools, like standard mincers but also can be equipped in special pre-breaking shafts wiht knives for frozen blocks. Models WW-130, WW-160 and WW-200 can be also equipped in cutting and separating system SINGRISET.