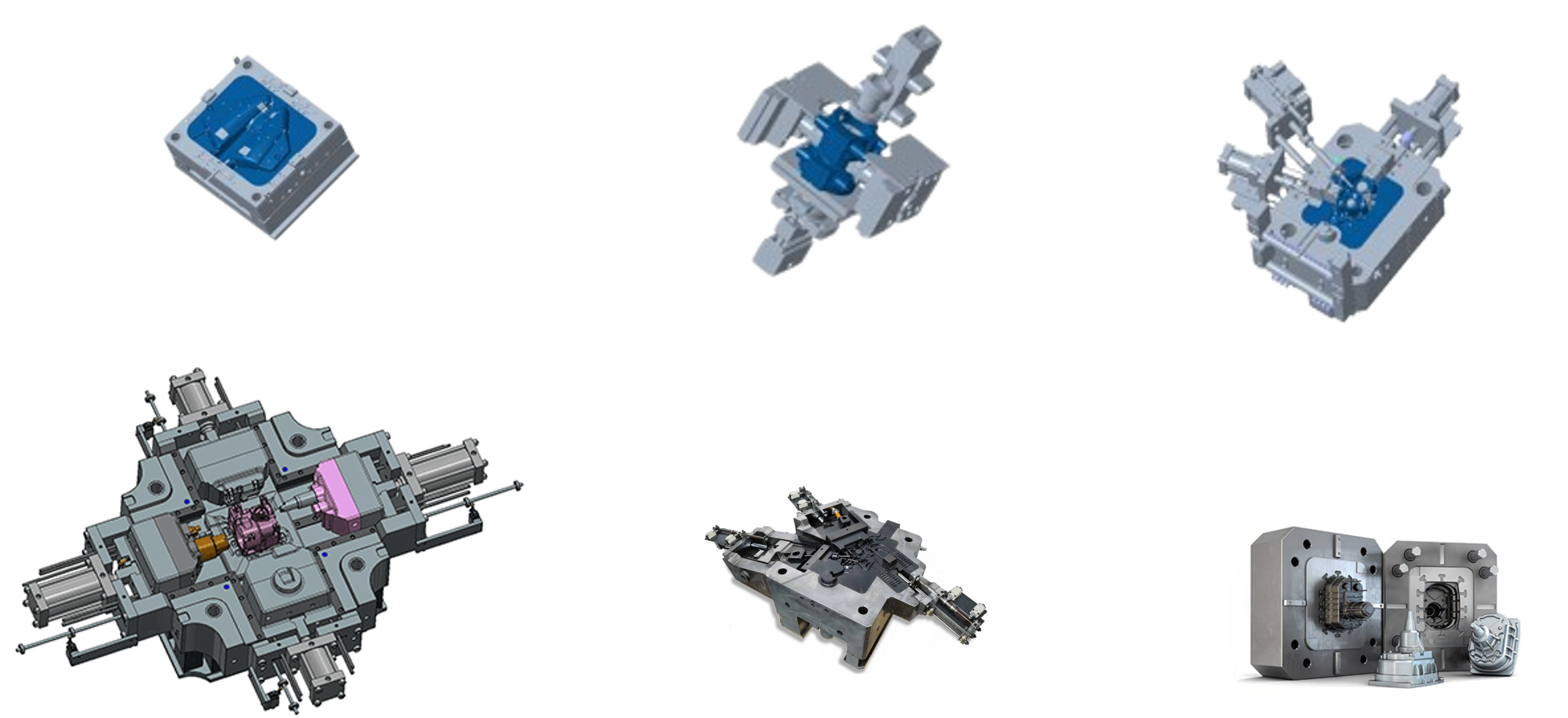

Dies & Mold Designing & Manufacturing

Atlas Engineering: Leaders in Precision Dies & Mold Manufacturing

State-of-the-Art Facility

Atlas Engineering boasts a cutting-edge facility, equipped with CNC Machining Centers, EDMs, a Die Spotting facility, and a 3D Scanner (GOM – Germany) for meticulous inspection. Our highly skilled team specializes in the manufacturing of premium-quality Dies & Molds, ensuring precision and excellence for every project.

Our Expertise

Dies & Mold Designing and Manufacturing:

High Pressure Die Casting Molds: Engineered for high performance and durability, our high-pressure die casting molds meet the most demanding industry standards.

Gravity Die Casting Molds: Designed to deliver exceptional results in gravity die casting applications, our molds are crafted with precision and reliability in mind.

Plastic Injection Molds: Our plastic injection molds are developed to provide efficient, high-quality production, catering to a wide range of plastic products.

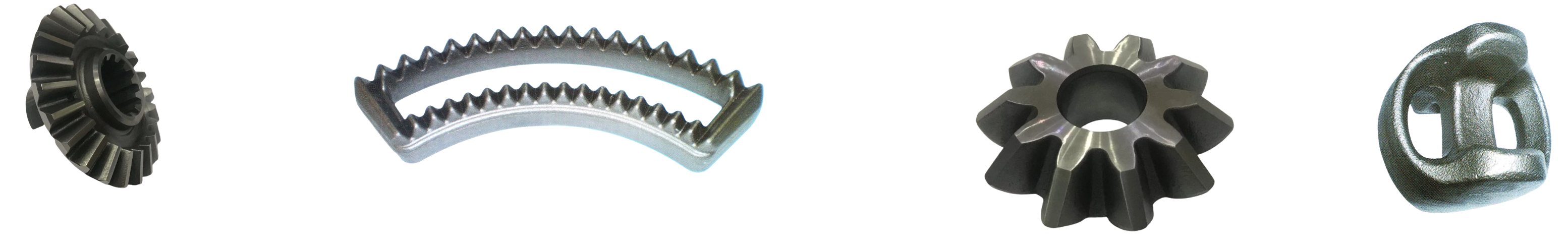

Cast Iron Foundry Dies: Robust and reliable, our cast iron foundry dies are built to withstand rigorous foundry operations, ensuring consistent and superior performance.

Advanced Equipment and Technology:

CNC Machining Centers: Our CNC machining centers offer high-precision machining capabilities, allowing us to produce intricate and complex components with unmatched accuracy.

EDMs (Electrical Discharge Machines): Utilizing advanced EDM technology, we achieve precise machining for even the most complex geometries.

Die Spotting Facility: Our specialized die spotting facility ensures perfect alignment and assembly of large molds, guaranteeing optimal performance.

3D Scanner (GOM – Germany): Equipped with the latest 3D scanning technology, we conduct thorough inspections to ensure every mold meets our stringent quality standards.

Heat Treatment Capabilities:

- Gas Nitriding NH3 / Hardening Furnaces (Seco Warwick): Our advanced heat treatment processes enhance the durability and performance of our dies and molds, providing long-lasting and reliable solutions.

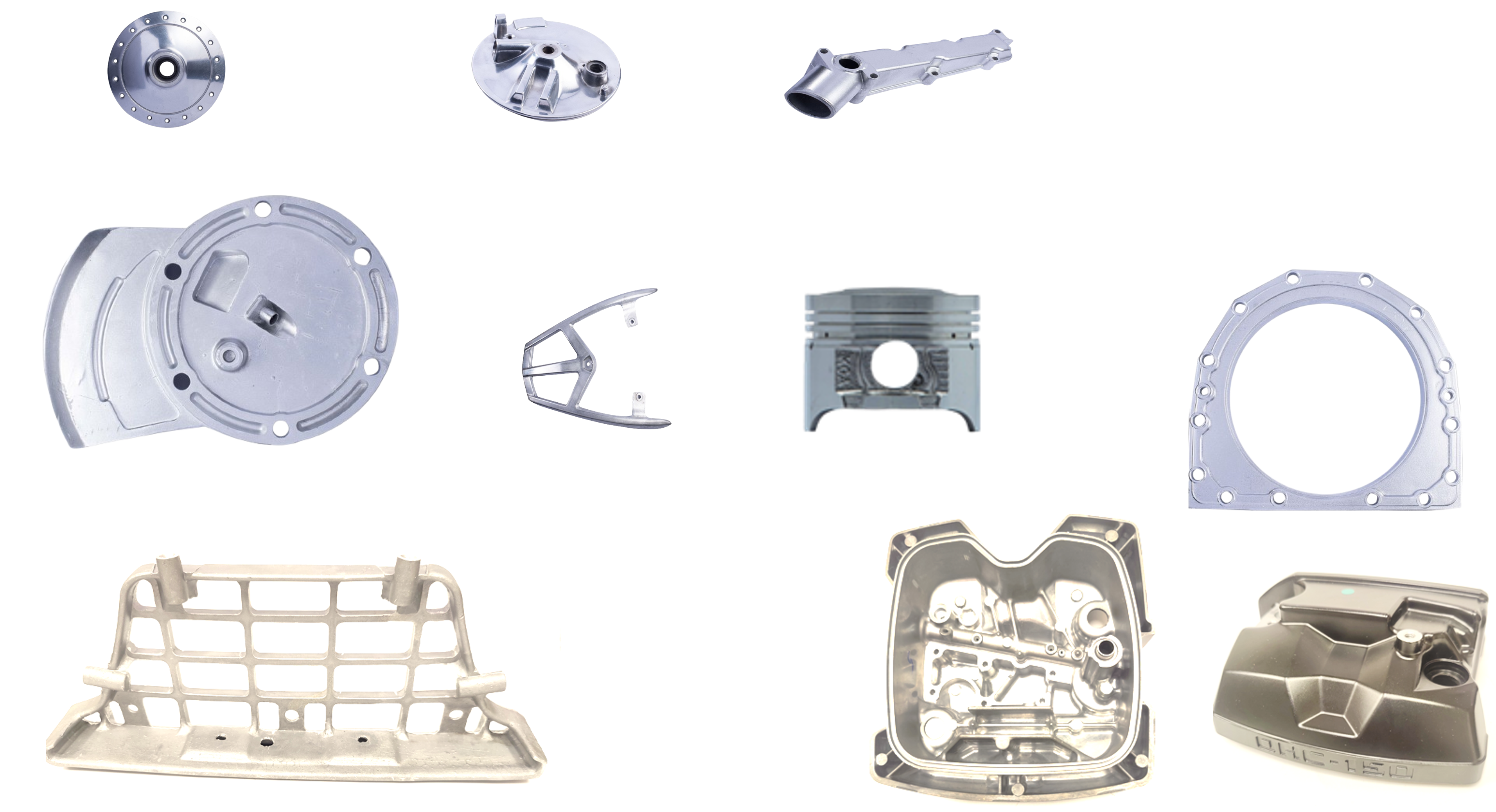

Materials We Use:

H13: Known for its toughness and wear resistance, ideal for die casting.

D2: A high-carbon, high-chromium tool steel renowned for its hardness and strength.

S45C: A versatile medium carbon steel suitable for general-purpose applications.

FC 450: A type of cast iron with excellent wear resistance and machinability.

Why Choose Atlas Engineering?

Innovative Technology: We leverage the latest advancements in manufacturing and inspection to deliver top-tier products.

Expertise: Our team of skilled professionals is dedicated to maintaining the highest standards of precision and quality.

Global Standards: We adhere to international quality and environmental management systems, ensuring reliability and sustainability.